Making More Stuff

Host David Pogue hits the road to explore the frontiers of invention and innovation. Airing October 16, 2013 at 9 pm on PBS Aired October 16, 2013 on PBS

Program Description

Broadcast Credits

IMAGE:

- Image credit: (David Pogue composite images)

- Courtesy: David Pogue/Flickr

Preview | 01:12

Full Program

Full program available for streaming through

Watch Online

Full program available

Soon

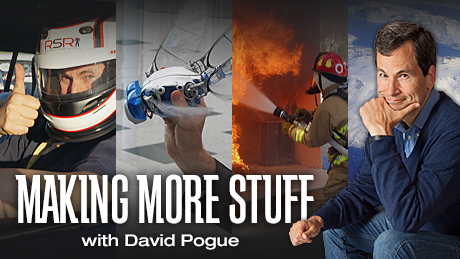

Making Stuff Faster

Host David Pogue tries to find out if there are physical limits to how fast we can go. Airing October 16, 2013 at 9 pm on PBS Aired October 16, 2013 on PBS

Program Description

Transcript

Making Stuff Faster

PBS Airdate: October 16, 2013

DAVID POGUE: We are living in the age of fast. Everywhere you look, scientists are discovering new ways to make stuff faster.

This is nothing! Gun it! Come on!

From ultra-fast electric cars…

It was like…

…to building machines that use human energy more efficiently than ever.

What is that?

Faster is not just about speed for speed's sake, it's also about how efficiently you can get things done, because time is money, big money.

Milliseconds are translating into millions of dollars a year?

HAROLD: It sure is.

DAVID POGUE: From discovering the quickest way to board a plane …

Man, there's got to be a faster way to load an airplane!

JASON STEFFEN (Fermi National Accelerator Laboratory): You know, there is a faster way to load an airplane.

DAVID POGUE: …to ultrafast internet connections…

CARLOS CASAS (Google Fiber Inc.): Speed tends to drive innovation.

DAVID POGUE: …going faster is transforming our lives.

Whether it's running a race, a stock trade, or exploring the universe, the history of human achievement is written by those who get there first.

NEIL ARMSTRONG (NASA, 1969 FILE FOOTAGE): That's one small step for man…

DAVID POGUE: I'm David Pogue. Join me on a quest to make stuff faster!

I'm a rocket man!

So why do we go faster? Sometimes to explore, sometimes to make money, and sometimes just because we want to win; case in point: the America's Cup, the world's most prestigious sailboat race.

So what happens when you take more than a century of engineering knowhow, add billionaire Larry Ellison and some of the world's best marine and aerospace engineers? What you get is not your father's sailboat.

How fast do these puppies go?

DIRK KRAMERS (Oracle Team USA): The top speeds are a little over 50 miles an hour.

DAVID POGUE: That's over twice the speed of a traditional sailboat.

DIRK KRAMERS: So, there's only one purpose. You just have to win a sailboat race, that's all.

DAVID POGUE: This is the Oracle, the United States' entry. It cost Ellison over one-hundred-million dollars, and he has hired the best crew money can buy. Australian Jimmy Spithill is the skipper.

JIMMY SPITHILL (Oracle Team USA): That high and the adrenaline and all that, it's just so addictive.

DAVID POGUE: Built almost entirely of carbon fiber, it's about the same length but four times lighter than a traditional America's Cup boat.

With just a few months to go before the race, I was invited onboard for a shakedown run. I'm one of the few non-crew members who's been allowed to sail with Spithill and his team.

And here we go. If you've been on a sailboat before, you might notice this is nothing like it. There's no galley, there's no bathroom, there's no wheelhouse. It's just pure speed.

Going faster in boats is not just about winning. For almost all of human history, every increase in nautical speed has shrunk the globe and exploded our horizons. Faster boats allowed the Phoenicians to bring the alphabet to the world, Columbus to discover America and Magellan to circle the earth.

Today, it's the speed of information that is rapidly shrinking our world—with ultrafast internet connections—and creating an economy where speed is measured in nanoseconds.

We are hardwired for speed, and whether it's pushing information to travel at the speed of light, or jumping out of a balloon to break the sound barrier, today we are smashing through limits long thought unbreakable.

But with speed comes danger. From high speed computer crashes roiling the financial markets…

NEWSCASTER (FILE FOOTAGE): This market is dropping precipitously.

DAVID POGUE: …to the high seas drama of the America's Cup, the faster we go, the harder we fall.

JIMMY SPITHILL: These boats reward pushing hard; you push too hard though, it can be catastrophic.

DAVID POGUE: There's safety everywhere. We're all harnessed to the boat, like this. We've got oxygen, got a knife, and we have bright orange sleeves, so if we go in the water, we're easy to spot.

The limit to how fast all things can go is determined by two factors. The first is energy, how much you can put into a system. Sailboats, obviously, get their energy from wind. But here, Oracle's engineers were able to smash through what you'd think would be a natural limit, the speed of the wind itself. The Oracle takes 15 miles an hour of wind and turns it into over 40 miles an hour of forward speed. And they do that by re-thinking the most basic element of a sailboat.

It might seem crazy, but this sailboat doesn't have a sail. Instead, it has a wing. This 131-foot-high carbon fiber wing is the boat's engine.

So how does this giant airfoil work?

SCOTT FERGUSON (Oracle Team USA): Hold this piece of paper to your mouth and blow. Blow along the top edge and see what happens to the piece of paper.

DAVID POGUE: Okay, whoa.

The paper is lifting for the same reason Frisbees® float and airplanes fly. In each case, wind traveling under the curved surface has a higher pressure than the wind above, creating lift. The same is true for sailboats, but the sail isn't horizontal, it's vertical. So here, the boat isn't pushed by the wind, it's pulled forward by low pressure.

Wow. In other words, it's sort of sucking you forward?

SCOTT FERGUSON: It's sucking you forward, exactly.

DAVID POGUE: To use the nautical term?

SCOTT FERGUSON: Yes.

DAVID POGUE: Traditional sails work the same way, but because they're flexible, they absorb some of the wind's energy. Boat designers have known for years that a rigid wing would be much more efficient. The problem was they were way too heavy. Carbon fiber changed that.

Bottom line: this boat doesn't sail, it flies.

The second key to speed is reducing resistance. As a boat moves through the water, it's slowed down by drag. So how do you solve that problem?

Their idea was to get this entire six-ton boat to lift out of the water and surf on a foil of carbon fiber.

KURT JORDAN (Oracle Team USA): It's an airfoil, just like a wing on an airplane. I mean, the fluid, whether it's air or water, accelerates over one surface faster than the other.

DAVID POGUE: In theory, it would rise up in the water just like an airplane through the air. But how about real life?

We should pick up speed, and if the boat goes fast enough, those foils in the water will do their thing and lift the boat out of the water.

The speed is intense. The thing lifts up out of the water, suddenly you're looking down 15 feet. It's like flying. It's like nothing you've done before.

After two years of training, the moment of truth arrives for Team Oracle. Their opponent, New Zealand, comes to the line in an equally innovative boat. In spite of all the technical breakthroughs that have gone into building the world's fastest boats, the America's Cup will come down to the people who sail them.

ANNOUNCER: The entire sailing world holds its breath, as they approach the line…

DAVID POGUE: The first team to win nine races takes home the America's Cup.

ANNOUNCER: …for the start of race number one of the 34th America's Cup. Three, two, one, go!

DAVID POGUE: With boats, I've learned that going faster is about how efficiently you can turn the energy put into the system, in this case the wind, into forward motion. With the America's Cup, the breakthroughs were in the sail and the underwater foil, but we can apply the same ideas to an even more basic form of human locomotion: running. From Pheidippides, who ran the first Greek marathon, to Roger Bannister smashing the four-minute mile, we've celebrated those who have run fastest.

Is there a way to make our mechanical systems, our bodies, more efficient and faster? To find out, I've come to Southern Methodist University, in Dallas, to have a friendly race against Don Miguel, a competitive sprinter from Trinidad. Our timekeeper: S.M.U. professor Peter Weyand.

PETER WEYAND (Southern Methodist University): Eleven flat; 18:04 for David.

DAVID POGUE: Weyand is a professor of speed. His lab is a high-tech lair, equipped with ultrafast cameras and a hundred-thousand-dollar treadmill, designed to measure the force of a runner's step.

Weyand believes that force is the key to speed, and he's about to show me why.

How fast is this?

PETER WEYAND: It's not as fast as it looks.

DAVID POGUE: This is nothing! Gun it! Come on! What do you got?

PETER WEYAND: Good!

DAVID POGUE: Wow. I'm like a human cheetah. Look at that! It's magnificent!

PETER WEYAND: Yeah, you look great in slow motion, David.

DAVID POGUE: Though I may be slow, when I looked at Don and me in slow motion, I was struck, not by the differences, by the similarities.

PETER WEYAND: So, what you can see is the time each of you spends in the air and the time that each of you takes to pick the limb up and put it back down in front of the body for the next step is about the same. And that's true, generically speaking, from Usain Bolt to little old ladies.

DAVID POGUE: Weyand has brought hundreds of runners through this lab, and it turns out that at top speed every one of them, including me, spends almost exactly the same amount of time repositioning limbs in between steps: about 0.3 seconds.

Our actual strides are happening, we're moving our legs, at the same speed?

PETER WEYAND: That's right.

DAVID POGUE: That guy and me?

PETER WEYAND: Competitive sprinter, you, a little old lady.

DAVID POGUE: Our legs all go at the same speed?

PETER WEYAND: The time to reposition the limbs is the same at the top speed of each of those runners.

DAVID POGUE: So what makes Don faster?

PETER WEYAND: What the competitive sprinters do is they hit the ground harder and hitting the ground harder makes your body move faster.

DAVID POGUE: When you put the graphs of Don's force and mine next to each other, the difference becomes clear. I'm hitting the ground with around 500 pounds of force; Don, 700.

The only part I don't understand is you're saying pushing down harder propels you forward faster, but it seems like pushing down harder would propel you up faster. I want to go that way.

PETER WEYAND: In the acceleration portion of a race, runners tend to lean forward so they can push backward, but that's a very short portion of a race.

DAVID POGUE: Weyand says after the first few steps, runners reach their maximum speed. From there, momentum keeps them moving forward. And the harder they hit the ground, the more time they spend in the air, and the more of their momentum they preserve.

PETER WEYAND: You push down on the ground with your limbs to pop back up, so you can maintain your forward momentum.

DAVID POGUE: This all seems well and good, but if force is speed, how do I increase mine?

PETER WEYAND: Typically, what the very fast people do is, (can we freeze it on the next contact?), when this foot comes down, the knees should be…in a good sprinter, those knees will be right together. If you eliminate the forward lean, get more upright, have your upper body be stiff, and then you want to smack the foot down hard.

DAVID POGUE: Upright posture, keep the lower body stiff, slam harder.

PETER WEYAND: Good! You felt a difference, didn't you?

DAVID POGUE: Yeah, I mean it felt like a totally different kind of running. I couldn't have told you if it was faster.

PETER WEYAND: The peak forces before were running at about 450 pounds per step. The peak forces after are well over 500: 525, 550. So that's a dramatic improvement in a matter of minutes, just from implementing a short set of instructions.

DAVID POGUE: Wow, that's amazing!

PETER WEYAND: If you can do that for the entire race, you should come down by at least a half a second to a second.

DAVID POGUE: Dog!

All right: body upright, rigid hips, hit the ground force down.

MAN: …set, go!

DAVID POGUE: Understanding the physics behind how we run…

PETER WEYAND: There you go: 16.7.

DAVID POGUE: I shaved two seconds!

…helped me more efficiently turn the energy from my muscles into speed.

To go faster and farther with those same muscles, you'd need a machine. From the first dugout canoe to the Daedalus, a human-powered plane, we have been building machines that try to get the most out of our engines: our bodies.

But the machine that really pushes the limits of human-powered speed is a bicycle. It's the most efficient human-powered vehicle there is. But what would you need to transform this humble means of transportation into a human-powered rocket? To find out, I went to Holland.

Hi, you must be Sebastiaan.

My guide is Delft University Human Power Team cyclist Sebastiaan Bowier.

SEBASTIAAN BOWIER (Delft University of Technology, Human Power Team): You want to go fast?

DAVID POGUE: He's invited me to go along for a ride.

SEBASTIAAN BOWIER: Come on.

DAVID POGUE: Sebastiaan keeps an eye on our speed.

SEBASTIAAN BOWIER: At the moment, we're going 20 miles an hour.

DAVID POGUE: He also has a meter to measure our power.

SEBASTIAAN BOWIER: And we're using about 350 watts.

DAVID POGUE: Three-hundred-fifty watts?

SEBASTIAAN BOWIER: Yeah.

DAVID POGUE: You make me sound like an electrical machine.

But it's true; it's the same kind of watts. The amount of power it takes to light up seven 50-watt lightbulbs is equal to the power I'm generating to go 20 miles an hour on this bicycle.

Three-hundred-fifty watts of raw TV-host-power! So: how to get more speed out of the energy I'm putting in?

I'm in the groove!

The answer is coming up fast.

I'm a rocket man! What was that?

SEBASTIAAN BOWIER: That's a recumbent.

DAVID POGUE: Recumbent?

SEBASTIAAN BOWIER: Yes.

DAVID POGUE: As in lying down?

SEBASTIAAN BOWIER: Yeah, you lay on your back, and because you are in a flat position, you have a lot less wind resistance.

DAVID POGUE: Whoa.

Almost half the wind resistance.

SEBASTIAAN BOWIER: So, at the moment, we're doing 350 watts…

DAVID POGUE: Compared to the racing bike, that 350 watts it took to go 20 miles an hour will get you…

SEBASTIAAN BOWIER: Twenty-five miles an hour.

DAVID POGUE: That's 25 percent faster with the same power.

So, that's cool. Just by making a few changes in the design, you wind up with the world's fastest bike concept.

WOUTER LION (Delft University of Technology): Yeah, except for that.

DAVID POGUE: What is that?

WOUTER LION: That's called the Velox3.

DAVID POGUE: Velox3.

The Velox3 has a singular mission: to become the world's fastest human-powered vehicle.

Sebastiaan is hoping that in a few months he can pedal it fast enough to break the record. It's a recumbent bicycle wrapped in an aerodynamic shell. Using the same 350 watts, today's top speed was 40 miles an hour, a 100 percent increase in speed over the conventional bike. And, believe it or not, that's nowhere near top speed.

SEBASTIAAN BOWIER: I was really easy peddling, because there is a lot of wind, so I didn't want to push it.

DAVID POGUE: That was easy peddling?

SEBASTIAAN BOWIER: Yeah.

DAVID POGUE: Sebastiaan's all-out power is 800 watts, which means he should be able to go…

WOUTER LION: Eighty miles an hour.

DAVID POGUE: Eighty miles an hour for a bike?

WOUTER LION: About, yeah it's about 80 miles an hour. That's, that's the goal of course.

DAVID POGUE: As a goal, sure, but 80 miles an hour on a bicycle? That would be more than twice as fast as the fastest Tour de France bike.

They took me into the Delft University human-powered lab to show me how they designed the Velox3 to do just that.

WOUTER LION: There are, in total, three bikes we've built.

DAVID POGUE: Each design is refined to further reduce wind resistance. Anything that creates drag is eliminated. And I mean anything.

SEBASTIAAN BOWIER: There is no window, so it's completely dark in there.

WOUTER LION: It's way better, aerodynamically, to put a camera at the back and just see through a screen.

DAVID POGUE: This all leads me to wonder, is it really even fair to call this thing a bicycle?

SEBASTIAAN BOWIER: It still has two wheels, and you have to power it yourself, so, yeah, it's a bike.

DAVID POGUE: It's sort of more of a rocket to me. As you might imagine, when you're piloting a human-powered rocket at speeds approaching 80 miles per hour, the stakes are high. This was Sebastiaan a year ago. Amazingly, he escaped without a scratch.

Now, one year later, he's back at the exact same deserted stretch of highway, in the Nevada desert, to break the world record of 82.8 miles per hour. With time running out, he pushes off for his final run.

He does it, piloting the Velox3 to a speed of 83.1 miles an hour, a new world record!

Of course if you want speed, who needs a bike? Try a '72 Buick Skylark, 350 small-block, and get some serious internal combustion muscle.

For all its failings, gasoline power is a cheap, efficient means of transportation.

What is that, a Matchbox® car?

JOHN WAYLAND (Plasma Boy Racing): It'll match your [expletive deleted], that's what it'll do. I don't think you know what you're picking on here.

DAVID POGUE: But, as I was about to find out…

Are you challenging me?

JOHN WAYLAND: I sure am.

DAVID POGUE: If you want to get more speed and power out of a car…

JOHN WAYLAND: To the track?

DAVID POGUE: See you there.

JOHN WAYLAND: All right then.

DAVID POGUE: …you have to unplug your old ideas about what makes cars fast.

ANNOUNCER: Next up, driving a 1971 Skylark, David Pogue faces off against John Wayland, in a 1972 Datsun.

DAVID POGUE: Whoa! What's going on here? Eleven-point-eight seconds? He blew my doors off!

What is this?

JOHN WAYLAND: It's a Datsun.

DAVID POGUE: I see it's a Datsun, but what's under the hood?

JOHN WAYLAND: You know what? More important, what's in the trunk?

DAVID POGUE: Oh my, what is it? A, a flux capacitor from Back to the Future?

JOHN WAYLAND: That is a lithium polymer battery pack.

DAVID POGUE: This is an electric car?

JOHN WAYLAND: You didn't know that?

DAVID POGUE: We're not talking about a Prius here. It may look like a 1972 Datsun, but underneath this humble exterior lurks the White Zombie, which holds the record for the world's quickest street-legal electric car.

So where is, like, the pistons and the carburetor?

JOHN WAYLAND: Pistons? There are no pistons; there is no carburetor. There is a controller, and there's an electric motor and there's a battery pack. It's that simple.

DAVID POGUE: That's the entire system?

JOHN WAYLAND: Yeah. It generates 538 horsepower.

DAVID POGUE: Now that's 50 percent more horsepower than my muscle car, but it's not the ponies that make the Zombie so quick.

JOHN WAYLAND: So, it's all about acceleration. And at the drag track, to accelerate, you need torque.

DAVID POGUE: Wait. So what do you mean by torque? I thought that's one of those things that's a, a spoon and a fork combined.

JOHN WAYLAND: Torque is turning force. It's the amount of energy you need to open a jar or turn a wrench. In the case of cars, it's the amount of force that's applied by the engine to the axle, to turn the car's wheels. It's usually measured in a unit called foot-pounds.

DAVID POGUE: And how many does this car get?

JOHN WAYLAND: 1250.

DAVID POGUE: That's more than a Dodge Viper and this souped-up Porsche, combined; more than any car on the road, ever.

So if this was stopped at a stoplight…

JOHN WAYLAND: Mm-hmm.

DAVID POGUE: …and you had the most powerful gas car in the world next to you…

JOHN WAYLAND: That would be a Bugatti Veyron, about a $2,000,000 car.

DAVID POGUE: …and the light turns green, this…

JOHN WAYLAND: The Bugatti would be looking at our tail lights instantly.

DAVID POGUE: Believe it or not, the hard part wasn't building a motor that powerful, it was figuring out a way to power it. In the case of the Zombie, to go from zero to 60 in 1.8 seconds, Wayland needed serious power, more than 50 Prius batteries' worth.

So how did he get that kind of juice? It took over 15 years of trial and error, dead-ends and false starts, until the answer came to him from the sky.

The batteries that start these Apache helicopters are some of the most the powerful and efficient around. They use lithium, a highly reactive element, which means it can store a lot of energy: six times as much, per ounce, as the lead in your car's batteries. Problem is, lithium-based batteries store so much energy that they can also get really hot and start fires. The solution was to combine it with manganese, which generates much less heat.

Wayland re-configured them to power the Zombie.

JOHN WAYLAND: There are 12 actual batteries.

DAVID POGUE: And not only do they allow him to go really fast, they also allow him to go farther on a charge.

JOHN WAYLAND: So, all of a sudden, my little car here, instead of just being quick and fast, we're going 100 miles on a charge.

DAVID POGUE: Okay, I'm sold. How much do you want for this?

JOHN WAYLAND: Oh, no, it's not for sale. Would you like to drive it though?

Okay. It's going to peel your face back a little bit. Your vision may get a little blurry at first, 'cause the blood runs out of your retinas.

DAVID POGUE: Oh, man!

JOHN WAYLAND: It's kind of like being shot out of a cannon.

You'll be fine, man.

DAVID POGUE: Thanks a lot. I think.

Wahoo! Yeah!

JOHN WAYLAND: Sucking amps, man!

DAVID POGUE: Sucking amps!

JOHN WAYLAND: Yeah!

DAVID POGUE: So far the breakthroughs I've discovered in making stuff faster have been tied to the speedometer, finding ways to cover more distance in less time. But there's a whole other breed of speed: it gets you there faster, not because you're breaking a speed limit, but because you're breaking a time limit.

It's called operations research or optimization, figuring out the fastest way to complete a task. It got its start in 1840, after Charles Babbage, the father of the computer, helped the British postal service figure out the most efficient way to deliver mail. Back then, scientists used slide rules to solve these kinds of problems; today they use supercomputers. So, you would think that it would be pretty easy to come up with a solution.

Well, it turns out that problems like this are still way too big for even the fastest computers. For example, what is the most efficient way to deliver 16 million packages a day? That's the problem that Jack Levis and his team at U.P.S. are trying to solve.

To understand what they're up against, let's pretend I have an Aunt Gertie, and I want to send a package to her. Its journey begins in San Francisco, Tuesday night at 8 p.m. By 2 a.m., Wednesday morning it lands in Philadelphia, only 140 miles from Aunt Gertie. Seven a.m.: it arrives here, at the U.P.S. shipping center in Gettysburg, Pennsylvania. It's already traveled over 2,500 miles in less than 12 hours. It would seem like the hard part's done, but, as I found out, it's just the beginning. Once it's on the truck, figuring out the fastest way to get it the final four miles to Aunt Gertie's, that's the real challenge. To do that, you have to solve a very difficult and complex math problem.

JACK LEVIS (United Parcel Service): The traveling salesman problem.

DAVID POGUE: Traveling salesman problem?

JACK LEVIS: The traveling salesman problem.

DAVID POGUE: What's that?

JACK LEVIS: It poses the question of what's the most efficient way to visit locations, just like a traveling salesman used to have to figure out.

DAVID POGUE: Simple right? Turns out that this problem has vexed generations of mathematicians.

JACK LEVIS: Let's say you have an office on Main Street, and you have three customers: one's on Elm, one's on High and one's on Maple. You know the time and distance between them, but what's the most efficient way to visit these customers?

DAVID POGUE: So, Elm, High, Maple, that's one. Maple, High, Elm, that's two. High, Elm, Maple: three; High, Maple, Elm: four. Four.

JACK LEVIS: Well, there's six. You know how I know there's six?

DAVID POGUE: How?

JACK LEVIS: With three customers, it's three times two, times one. There's six ways. If you double that to six customers, now there's 720 ways. At twelve customers, there's 479,000,000 ways.

If you have 25 locations to go through, there's fifteen-and-a-half-trillion-trillion different ways to visit 25 locations.

DAVID POGUE: Trillion-trillion?

So if a 25-stop route has trillions and trillions of possible combinations, imagine how many possibilities there are in the 140-stop route that will take my package to Aunt Gertie.

JACK LEVIS: There's not even a number to articulate this. There's more ways to deliver this route than the number of nanoseconds the earth has been in existence.

DAVID POGUE: So, if the traveling salesman problem is too tough for the world's largest computer, how do you solve it? By building a smarter program. It's called Orion.

How does it actually calculate the route?

JACK LEVIS: Well, it's going to start with something that's just very simplistic. It's not going to think like you, thinking ahead. It's going to say, "Who's my nearest neighbor?" So it's going to start at the beginning. "What's closest to me?" It might go to the next stop closest. So, when it's done, in its very first iteration, it's created a route that looks like a kindergartener would have created. And then it says, "Now, what's wrong with that?"

DAVID POGUE: In this case, it does that by breaking the task down into sets of smaller problems, each with five variables with 120 possible solutions. The first step is starting with clusters of five stops and figuring out the most efficient way to deliver packages within that cluster. It arranges them into larger groups of five and figures out the most efficient way to move between them. Finally, it connects them all together and arrives at a solution, with only thousands of calculations, total. And it does all this in a few seconds. But that's just the start.

JACK LEVIS: We have 8:30s; we've got 10:30s; we've got noons.

DAVID POGUE: Deliveries promised by a certain time; throw those into the mix, and it makes finding a solution nearly infinitely more difficult.

JACK LEVIS: Now you try to do that on your own and think of the number of combinations you would have to think through.

DAVID POGUE: Now here's the thing, Orion is not looking for the perfect solution, it's looking for an optimal solution that can be figured out in a few seconds. The question: is this better than what a human without a time limit could come up with?

With human pride on the line, I decided to pit man versus machine and see if I could come up with a quicker way to get to Aunt Gertie's house.

All right, so how do I compare with Orion?

JACK LEVIS: The only way to know is to give it a try. You ready to "brown up?"

DAVID POGUE: Excuse me?

Before I do my own route…

Permission to come aboard sir?

...I have to do a little boot camp. I ride with veteran driver Tim Ahn.

TIM AHN (United Parcel Service): I've done it for close to 10 years.

DAVID POGUE: Tim says it's not just about planning the fastest route, it's about how fast you can get that route done.

TIM AHN: Perpetual motion.

DAVID POGUE: Multi-tasking.

TIM AHN: Okay, I've got to move along here.

DAVID POGUE: Have you ever delivered a baby or…?

TIM AHN: I've never done that.

DAVID POGUE: I'm ready to put my traveling salesman solution to the test.

JACK LEVIS: You've got four next-day-air packages that have got to be done by 10:30. This one by 3 p.m. You got business customers that need to be delivered earlier part of the day.

DAVID POGUE: Okay.

JACK LEVIS: Pick-ups, they can set their watch by the time we get there.

Good luck. That's logistics buddy.

DAVID POGUE: The challenge here: me driving my route and Tim driving Orion's.

U.P.S.

JACK LEVIS: It's 10:30. Tim's completed 28 stops, which is pretty good. David's only got 21 stops off by now. Twelve-thirty: Tim's got 48 stops done, and he's on lunch. David's actually catching up, he's gotten 54 stops done by now, but he hasn't even taken his break. He's got to start that hour break right now.

TIM AHN: U.P.S.

JACK LEVIS: It's 2:30, and, you know, they're neck and neck right now. Tim's delivered 73 stops and David's at stop 74. So, they're neck and neck, but David still has some businesses he hasn't delivered yet. Four-thirty: Tim's now moving well ahead of David. You know, those businesses are going to close in the next hour.

DAVID POGUE: U.P.S.

JACK LEVIS: It's 6:28, and Tim is back in the building. David's got 10 more stops to do.

DAVID POGUE: Surprise!

AUNT GERTIE: Oh, my gosh! What have you been up to?

Oh, my goodness. It looks exactly like you.

DAVID POGUE: Oh, thank you.

AUNT GERTIE: Oh, I love it!

It's been such a long time.

DAVID POGUE: Yes, it has. Now, could you just please sign here? Great. See you.

AUNT GERTIE: You bet.

JACK LEVIS: It's 7:04, and David is just now coming in, 25 or 30 minutes later than Tim.

We've got to talk.

For a first-timer, looking at an as-a-crow-flies solution, it's really pretty good, but you are about 10 miles over our Orion solution.

If every driver just drove one additional mile per day, after a year, that'd be 30-million dollars. So, 10 miles for us…

DAVID POGUE: Three-hundred-million dollars.

JACK LEVIS: ...is a lot.

DAVID POGUE: And it only gets worse. My route took 39 minutes longer than Orion's to complete. Company-wide, that would be a loss of millions of hours a year.

JACK LEVIS: We'd be out of business. I'm sorry, David, but I need the browns back.

DAVID POGUE: You're firing me?

Well, I'd had a good run, but I was no match for Orion, with a plan that would, at best, bankrupt one of the largest shipping companies in the world. It was time for me to move on.

From getting packages there on the ground, to getting people there by air, these kinds of problems are everywhere you look. Case in point: did you ever feel like you spent more time boarding a plane than actually flying in it?

Oh, man, there's got to be a faster way to load an airplane!

JASON STEFFEN: You know, there is a faster way to load an airplane.

DAVID POGUE: Who are you?

JASON STEFFEN: I'm Jason Steffen.

DAVID POGUE: You've spent some time thinking about how to load a plane, have you?

JASON STEFFEN: Yeah, I wrote a computer model, ran some simulations.

DAVID POGUE: Are you, like, a computer scientist or something?

JASON STEFFEN: No, I'm an astrophysicist.

DAVID POGUE: So how does an astrophysicist from Fermilab get so fired up about finding a faster way to board a plane?

GIRL: Don't touch me!

DAVID POGUE: By getting stuck in line waiting for one.

JASON STEFFEN: I just thought to myself, there's got to be a better way to do this.

DAVID POGUE: Not a difficult problem, or so he thought.

JASON STEFFEN: The answer was obvious, that you should board from the back of the plane to the front. And so, I wrote a piece of software. When I ran it, turned out that it wasn't the best way. It seemed to be exactly the same as what I thought the worst way was, which would be boarding from the front of the plane to the back.

DAVID POGUE: Out of ideas, he was overwhelmed by the sheer number of possible plans he might have to try before arriving at the solution.

JASON STEFFEN: The number of possible ways of boarding an airplane with a hundred-and-fifty passengers would be, like, a hundred-and-fifty factorial.

DAVID POGUE: You remember factorials.

JASON STEFFEN: That's 150 times 149 times 148 times 147.

DAVID POGUE: Just like U.P.S. and the packages, this was too big a problem for a computer to handle.

So what did you do?

JASON STEFFEN: I did kind of a Monte Carlo-type simulation.

DAVID POGUE: What's a Monte Carlo simulation?

JASON STEFFEN: Just like a casino with gambling, and Monte Carlo, you basically roll the dice.

DAVID POGUE: Over and over again, each time asking a question.

JASON STEFFEN: Does this change make an improvement? If so, then I'll accept it; if not, then I won't accept it.

DAVID POGUE: In this case, instead of random rolls of the dice, he ran random plane-boarding simulations, each time keeping the faster and throwing out the slower. Through this process of elimination, the computer came up with what Jason thinks is the best solution.

JASON STEFFEN: The way my method works is the first wave of passengers are going sit in the even numbered rows, every other row, in the window seats. And then you proceed to the odd numbered rows, in the window seats. Then to the middle seats, then to the aisle seats.

DAVID POGUE: But there's a catch. In order for Steffen's plan to work, the passengers have to board in 16 different groups. If they don't precisely follow the sequence, the system will break down.

DOUG LAWSON: Yeah, well, I don't think so. There's no way that's going to work.

DAVID POGUE: And who are you?

DOUG LAWSON: I'm Doug Lawson, paleontologist.

DAVID POGUE: A paleontologist? We're talking about boarding airplanes here!

DOUG LAWSON: Well, I actually work for Southwest Airlines.

DAVID POGUE: He really is a paleontologist, and he does work for Southwest Airlines.

On the first count, he discovered one of the largest creatures ever to fly the skies. On the second, he makes planes board faster.

And what is his plan?

DOUG LAWSON: Well, what we do is just let people get on and fill the plane up.

DAVID POGUE: Southwest has no assigned seats. It just has passengers line up, board and sit where they want.

Sounds like chaos.

DOUG LAWSON: Oh, yeah, it seems like that, but people interact with one another, and we just set it up so that we get the benefit from their behavior.

DAVID POGUE: Lawson developed this plan after running hundreds of different, and, I might add, rather unusual simulations.

DOUG LAWSON: People refer to these simulations as "ant simulations."

DAVID POGUE: Ants? But we're talking about airline passengers.

DOUG LAWSON: Airline passengers are like ants in that they all have an individual job: they've got to get to a seat. And you watch what emerges as those individuals interact.

DAVID POGUE: What emerges, he says, is order rather than chaos and, most importantly, speed.

It's a shame we can't compare the two systems.

DOUG LAWSON: Yeah, well, we can! We've got a line of people waiting to get on a plane, right? Let's do a couple of experiments.

DAVID POGUE: We're going to have a battle? A battle of the plane boarding systems?

DOUG LAWSON: Right.

DAVID POGUE: Awesome!

What we have here is a Southwest Airlines 737, with which we intend to perform a historic experiment. We're going to find out, once and for all, what is the fastest way to board an airplane.

Ladies and gentlemen, welcome to the Sky Harbor International Airport Airplane Boarding Smackdown.

In this corner, from Fermilab, in Batavia, Illinois, the challenger, weighing in at 155 pounds, creator of the Monte Carlo plane boarding system, Jason "the Supernova" Steffen. And in this corner, the champion, from Niotaze, Kansas, creator of the Southwest Airlines open boarding plan, Doug "the Dinosaur" Lawson.

You know the players. You know the plans. Let's get down to business!

FLIGHT ATTENDANT: After the A group has boarded…

DAVID POGUE: First up, the Lawson open boarding plan: passengers sit wherever they like, the current industry standard for speed.

FLIGHT ATTENDANT: This is going to be a completely full flight.

DAVID POGUE: Everyone is set, queued, ready to go. And start the clock!

DOUG LAWSON: And so they'll start filling in in the front here, so you can see…

DAVID POGUE: Doug, I see we're having an overhead bin problem in 23, what's going on there?

DOUG LAWSON: Yeah, well, you know they're going to have to squish it down to try to get it in there.

DAVID POGUE: You know what they say, Doug. If it weren't for the passengers, this would be a pleasant business.

DOUG LAWSON: Right. We'd always be on time.

DAVID POGUE: Now this is going very, very smoothly, as I can see here.

Jason Steffen, I've got to imagine this is making you sweat a little bit.

JASON STEFFEN: One of the things that you run into, because people don't want to sit in the middle, is that eventually, people are going to have to start climbing over the person in the aisle seat.

DAVID POGUE: And looks like we're complete. Stop the clock! Stop the clock! Ten minutes, forty seconds, an impressive time to beat.

And we're ready for round two.

JASON STEFFEN: Tickets.

DAVID POGUE: We're going to board the same aircraft using the Jason Steffen plan.

JASON STEFFEN: That's A-52.

SOUTHWEST AIRLINES PASSENGER: Perfect.

DAVID POGUE: Steffen's plan, as you remember, is to divide folks into sixteen different groups. Have them sit in the windows first, then middles, and finally aisles. A great idea, in theory. But as we're seeing, it requires a lot of planning and direction.

SOUTHWEST AIRLINES PASSENGER: All right, thank you.

DAVID POGUE: And start the clock!

Welcome aboard.

So, if everything goes smoothly, you won't have people ever climbing over each other, or having to get out to let a middle in, because the windows will all be in first, the middles will all follow.

JASON STEFFEN: Right, and that's what's happening right now. Right now, you know, people are filing in.

DAVID POGUE: Doug, give me a critique of what might fail with this system.

DOUG LAWSON: If you can't get the window people in first, then we're going to see these jam-ups, if people were not in order.

DAVID POGUE: And sure enough, at barely two minutes in, a breakdown in the order.

JASON STEFFEN: It looks like that person,…they're not supposed to be sitting there.

DAVID POGUE: Oh, it appears, in other words, that the Steffen plan might be unraveling at the edges, just as Lawson predicted.

JASON STEFFEN: And because of that, the line's kind of backing up here a little bit.

DAVID POGUE: That should not be happening.

JASON STEFFEN: The worst that can happen is that it turns into, basically, a random boarding process all over again.

DAVID POGUE: I hate to say it, Jason, but I'm seeing a little bit of that, right now.

DOUG LAWSON: Even if you just put people on randomly…

JASON STEFFEN: They'll spread out.

DOUG LAWSON: …they would spread out.

DAVID POGUE: When you guys say it that way, it makes it sound like the system used by most of the industry, is about the dumbest possible way.

DOUG LAWSON: Yeah.

JASON STEFFEN: Yeah, that's about right.

DAVID POGUE: At six minutes in, it looks like the Steffen plan has turned a corner. The passengers seem to have finally gotten the hang of his system.

DOUG LAWSON: It's looking pretty good.

DAVID POGUE: Indeed it is, they're bolting for the window seats. Alternate rows. The aisle is being used much more efficiently because there's…

JASON STEFFEN: There's lots of people putting their luggage away at the same time.

DAVID POGUE: I must say it's going very smoothly now.

And it looks like we're complete! Stop the clock!

Seven minutes, fifty-seven seconds! A 34 percent improvement!

So while Steffen's plan won handily, by a blistering two minutes and forty-three seconds, Lawson says, because it required such a precise boarding system, in the real world, it would not fly.

DOUG LAWSON: It required so much detailed control over the whole process to get it to happen that way, and you just cannot get that kind of control in a real setting.

DAVID POGUE: And so tonight it seems that Jason Steffen may have won, but in theory, probably not in practice. What does he have to say about that?

JASON STEFFEN: I'm speechless.

DAVID POGUE: We've discovered that, in the business world, doing things faster is a science, and it can be used to squeeze out every last bit of inefficiency, saving time and making money. But what if you could move the information itself faster?

For centuries businessmen have been in an information arms race. The story is told that in the 19th century, Nathan Rothschild used a carrier pigeon to receive the news of Napoleon's defeat at Waterloo and made a fortune with that one piece of information. Today, information travels in beams of light, through fiber optic cables. That would have to be as fast as one could go, right?

Well, not so fast, this is how they used to buy and sell stocks; this is how they do it today.

This is Tradeworx headquarters, in Red Bank, New Jersey, one of the largest stock trading firms in the country. And these guys sitting at desks, they're not trading stocks, they're just babysitting the computers that do.

MANOJ NARANG (Tradeworx): Computers are doing 100 percent of the work. They're making all the decisions and they're doing all the trades.

DAVID POGUE: It's called high frequency trading. Buying and selling stocks in fractions of a second, often making less than a penny a share.

MANOJ NARANG: Average profit margin is ten percent of a cent, per share.

DAVID POGUE: But it adds up to millions, because along with speed comes volume.

MANOJ NARANG: Our firm trades over one percent of the daily market volume of the stock market—around a hundred million shares a day—so it becomes a meaningful amount.

DAVID POGUE: Right.

To make that meaningful amount, traders need to be the first to get information about prices. Speed is money.

MANOJ NARANG: In a very real way, speed is money.

DAVID POGUE: And a war has broken out between traders to get that money. The weapon: the computer networks that move financial information.

MANOJ NARANG: So, a very interesting part of the so-called "high-tech arms race" is the transmission of information across long-distance financial corridors, none of which is as important as the Chicago to New York corridor.

DAVID POGUE: Some stocks trade on exchanges in both New York and Chicago, but say a particular stock is selling for a penny less in the Chicago market. Buying that stock in Chicago, then immediately selling it in New York could turn a quick profit for whomever does it first.

MANOJ NARANG: The question is: how can you be making decisions based on the most current financial information?

DAVID POGUE: Speed has been important in the markets since the advent of markets.

DAVID POGUE: For over 150 years, buy and sell orders were transmitted over copper cable, which ran along rail lines. It took a quarter of a second for a message to complete the 2,000-mile roundtrip. And for more than a century, there wasn't any faster way, until fiber optic cable came along, in the 1980s, zig-zagging its way along the same path.

Instead of copper, fiber optic is made of glass cable, and carries messages in beams of light instead of electricity. It takes a beam of light fourteen-and-a-half milliseconds for a roundtrip on this same path, fourteen-and-a half-thousandths of a second. So how can they get faster than that?

MANOJ NARANG:Straightest possible path.

DAVID POGUE: A straight line between New York and Chicago is 720 miles.

MANOJ NARANG: But it's virtually impossible to build that route, because you have to actually go through people's property, you have to actually go through the water.

DAVID POGUE: Virtually impossible, but one of their competitors tried. It's that blue line. While they couldn't make a straight shot, their new path lopped about 175 miles off the existing one, bringing the roundtrip time down to 13.1 milliseconds. That's 1.4 thousandths of a second faster.

MANOJ NARANG: That sort of differential can translate into millions of dollars of profit or loss over the course of a year.

DAVID POGUE: Could anyone beat that?

Reluctant to leave that money on the table, Tradeworx thinks they have found a way to get even faster.

MIKE BELLER (Tradeworx): Yes!

DAVID POGUE: Tradeworx chief technology officer Mike Beller showed me what he says is the future of high speed trading. It looks something like a New Jersey used car lot.

DAVID POGUE: I think it might be a New Jersey used car lot. And next to it is our secret—or maybe not so secret—weapon in how to get from Chicago to New York faster than the next guy.

DAVID POGUE: Wow.

MIKE BELLER: Come on through here and take a look up. This is a microwave tower.

DAVID POGUE: Wait, a microwave tower?

MIKE BELLER: Yes, a microwave tower.

DAVID POGUE: Whoa, whoa, whoa!

FILM FOOTAGE: …microwave beam transmission.

DAVID POGUE: Isn't this old technology, from phone companies of the 1950s?

Even so, their plan is to set up a network of dozens of these to bounce financial information between Chicago and New York.

But I still don't understand how this can be faster than a fiber optic cable.

It's my impression that light generally travels at the speed of light.

MIKE BELLER: It does.

DAVID POGUE: So how could anything be faster than the speed of light?

MIKE BELLER: It just turns out that the speed of light in glass is a lot slower than the speed of light through the air. Light can travel this one foot of fiber in about one-and-a-half nanoseconds.

DAVID POGUE: That seems pretty fast.

MIKE BELLER: It does, but in the air, the microwave signal only takes one nanosecond to go a foot.

DAVID POGUE: What's the total time savings from here to Chicago?

MIKE BELLER: Round trip, on the order of five milliseconds.

DAVID POGUE: Shaving off those five milliseconds means they would get the roundtrip time down to eight-and-a-half-thousandths of a second. If they accomplish that, they'll gain an advantage that could make their customers tens of millions of dollars a year.

MIKE BELLER: Seems like a good deal.

DAVID POGUE: Speed is money, man.

MIKE BELLER: It sure is.

DAVID POGUE: Hey!

So, great, those guys are off making millions of dollars every millisecond with their superfast connections, while I'm waiting for the rest of the show to download.

TOM MORGAN (Polytechnic Institute of New York University): Hi, David.

DAVID POGUE: Who are you?

TOM MORGAN: I'm Tom Morgan, from Flatbush.

DAVID POGUE: Flatbush?

TOM MORGAN: Yeah, I, I'm a researcher in supercomputing at N.Y.U. Poly.

DAVID POGUE: He really is a computer scientist, and he really is from Flatbush, Brooklyn.

TOM MORGAN: You seem to be having some problems with your download.

DAVID POGUE: Well, is there anything I can do about it?

TOM MORGAN: Well, you can't build your own network, like the traders did, but you can go to Kansas City, and we can conduct a little experiment there.

DAVID POGUE: Kansas City?

Anyone home?

CHRISTOPHER BARAN (TravelingNuker): Hi. Welcome to the future.

DAVID POGUE: The future? This looks like a frat house filled with pizza-eating geeks.

CHRISTOPHER BARAN: You're in one of the homes of the Kansas City Startup Village.

DAVID POGUE: …the next generation of venture capitalists, software designers, artists and engineers.

CHRISTOPHER BARAN: So, I heard you were having some trouble trying to download your show.

DAVID POGUE: Okay, how does everybody know this?

CHRISTOPHER BARAN: Seeing the little buffer thing?

DAVID POGUE: Yes.

CHRISTOPHER BARAN: That'll never happen.

DAVID POGUE: They've all moved to Kansas City, because that's where the speed is.

CHRISTOPHER BARAN: The fastest internet connection that you can get in the United States, right now.

DAVID POGUE: And how fast is fast?

CHRISTOPHER BARAN: About 200 times faster than the average connection.

DAVID POGUE: 200 times!

The connection I was using to download the show was 5 megabits per second.

Okay, and how fast is yours?

CHRISTOPHER BARAN: One thousand.

DAVID POGUE: So where does this speed come from?

Internet giant Google has come to town and is wiring the city with…

CARLOS CASAS (Google Fiber): Fiber optic cables.

DAVID POGUE: Haven't we just been through this?

Have you considered microwaves?

CARLOS CASAS: Right now, what we have is strands of glass that transmit light.

DAVID POGUE: Yeah, fiber optic cable. The nation's internet runs on something called a backbone: a network that moves data all around the country. Now, the backbone is fiber optic cable that runs underground and on telephone poles.

CARLOS CASAS: But then they'll use copper from the pole to the home, which, really, you know, slows down the connectivity.

DAVID POGUE: That's because torrents of data, flowing at lightning speeds over fiber, slow to a trickle when they hit that old copper line running into your house.

CARLOS CASAS: What we do with our service is we are actually bringing a strand of fiber directly into a person's home. Which allows us to transmit speeds at much faster than what they're used to.

DAVID POGUE: Now this kind of speed does not come cheap; it costs upwards of $500 to wire the average house with fiber optic. But the hope is that as other internet providers follow—and some already have—the price will drop.

And what kind of difference would that make to my everyday life?

TOM MORGAN: Hi, David.

DAVID POGUE: Hi, Tom.

TOM MORGAN: How's Kansas City?

You know, David, you were having trouble downloading your TV show. Maybe we can have just a little race.

DAVID POGUE: Fastest internet in the country here, against your pathetic Brooklyn internet.

TOM MORGAN: I'm ready any time.

CHRISTOPHER BARAN: Three, two, one, go!

DAVID POGUE: Whether it's pushing the speed that information travels over the internet, or attempting a world speed record on a remote desert highway, or sailing faster than the wind…

ANNOUNCER: Race Number One of America's Cup.

DAVID POGUE: …speed isn't just about pushing the limits of our bodies; it's about pushing the limits of our ingenuity.

Thirty seconds left. What do you got remaining?

TOM MORGAN: Forty-five minutes.

DAVID POGUE: One thing is for certain…

CARLOS CASAS: Speed tends to drive innovation.

DAVID POGUE: Speed is transforming our world.

VIDEO: …a relatively unknown communication system called "the internet."

CARLOS CASAS: When we went from dialup to broadband, all of a sudden, social media, even Google became possible.

VIDEO: Over 25-million people will be using it by the year 1998.

DAVID POGUE: In less than a decade, we've come to take for granted the access to information, art and commerce that high-speed connections make possible.

But it's just the start…

CHRISTOPHER BARAN: There are some things that are going to happen that we can't even imagine.

DAVID POGUE: …because, at its best…

VIDEO: Modern equipment speeds up the world.

DAVID POGUE: …technology intended only to make things faster…

VIDEO: …a highly sophisticated computer.

DAVID POGUE: …changes the way we live our lives.

CHRISTOPHER BARAN: Those were foreign concepts. Now, with the internet, there's some things that we're going to have happen that we don't even know exist yet.

DAVID POGUE: Four, three, two, one…we are done! How are you doing, Tom?

TOM MORGAN: Oh, about, oh, 44 minutes.

DAVID POGUE: But speed alone won't get us there; we still have to chart the course.

U.P.S. Surprise!

DAVID POGUE: I haven't seen you in years!

DAVID POGUE: It was Sebastiaan Bowier's skill as a rider that propelled him to a world record. In the America's Cup, the Oracle pulled off one of the greatest comebacks in sports history.

ANNOUNCER: Emirates Team New Zealand eight wins to one. They were sitting on match point.

DAVID POGUE: After losing eight of the first nine races, the sailors of the American team fought their way back.

ANNOUNCER: And it is Oracle Team USA that is just moments away from keeping the Cup.

DAVID POGUE: Proving, once again, that no matter how fast the boat, it's still the sailor who wins the race.

We can't know where faster will take us, but one thing seems certain: since our quest for speed is fueled by our curiosity, we will continue making stuff faster.

Broadcast Credits

- Host

- David Pogue

- WRITTEN BY

- Michael Bicks

- DIRECTED AND PRODUCED BY

- Michael Bicks

Vincent Liota

Anna Lee Strachan - EXECUTIVE PRODUCER

- Chris Schmidt

- ASSOCIATE PRODUCER

- Karinna Sjo-Gaber

- EDITED BY

- Daniel Gaucher

Vincent Liota - DIRECTOR OF PHOTOGRAPHY

- Jason Longo

- ADDITIONAL CAMERA

- Stephen DeRespino

Dan Dominy

Jon Gay - SOUND RECORDISTS

- Neil Bontrager

Michael Boyle

Steve Clack

Peter Deutscher

Rusty Duggan

Michael Haines

Hugh Scott

Tyler Stephens

Willem de Wijs - DIGITAL IMAGING TECHNICIAN

- Leonardo Reyes

- MAKE UP

- Donatelle Mascari

- MUSIC

- Christopher Rife

- ART DIRECTOR

- Ekin Akalin

- ANIMATION

- Vincent Liota

Handcranked Productions

Smash5 Studios

Doug Quade - ADDITIONAL EDITING

- Max Powers

- ASSISTANT EDITOR

- Jim Fetela

- ONLINE EDITOR AND COLORIST

- Michael H. Amundson

- AUDIO MIX

- Heart Punch Studio, Inc.

- RESEARCH

- Shraddha Chakradhar

Barbara Moran - PRODUCTION ASSISTANT

- Devin McCloskey

- ASSISTANTS TO DAVID POGUE

- Jan Carpenter

Cindy Love - ARCHIVAL MATERIAL

- Corbis

Getty

Google Fiber

Human Power Team, Delft University of Technology

iStock

Johanna Lee Productions LLC

John-Michael Bills

Michael W. Sullivan

ORACLE TEAM USA

UPS - SPECIAL THANKS

- Lori Cooper

Mike Miller

Portland International Raceway

Southwest Airlines

UPS - ADVISORS

- Jim Collins

Tony DeRose

Dale Dougherty

Alex King

Tim McGee

Amy Moll

Mike Petrich

Ainissa Ramirez

Thea Sahr

Eric Siegel

Stephen Streiffer

Desney Tan

Jessika Trancik

Thomas Tretter

Phil Weilerstein - NOVA SERIES GRAPHICS

- yU + co.

- NOVA THEME MUSIC

- Walter Werzowa

John Luker

Musikvergnuegen, Inc. - ADDITIONAL NOVA THEME MUSIC

- Ray Loring

Rob Morsberger - CLOSED CAPTIONING

- The Caption Center

- PUBLICITY

- Eileen Campion

Victoria Louie - SENIOR RESEARCHER

- Kate Becker

- NOVA ADMINISTRATOR

- Kristen Sommerhalter

- PRODUCTION COORDINATOR

- Linda Callahan

- PARALEGAL

- Sarah Erlandson

- TALENT RELATIONS

- Scott Kardel, Esq. Janice Flood

- LEGAL COUNSEL

- Susan Rosen

- DIRECTOR OF EDUCATION

- Rachel Connolly

- DIGITAL MANAGING PRODUCER

- Kristine Allington

- SENIOR DIGITAL EDITOR

- Tim De Chant

- DIRECTOR OF NEW MEDIA

- Lauren Aguirre

- DEVELOPMENT ASSOCIATE

- Lisa Leombruni

- UNIT MANAGER

- Ariam McCrary

- PRODUCTION MANAGER

- Stephanie Mills

- POST PRODUCTION ASSISTANT

- Brittany Flynn

- POST PRODUCTION EDITOR

- Rebecca Nieto

- POST PRODUCTION MANAGER

- Nathan Gunner

- COMPLIANCE MANAGER

- Linzy Emery

- BUSINESS MANAGER

- Elizabeth Benjes

- DEVELOPMENT PRODUCER

- David Condon

- PROJECT DIRECTOR

- Pamela Rosenstein

- COORDINATING PRODUCER

- Laurie Cahalane

- SENIOR SCIENCE EDITOR

- Evan Hadingham

- SENIOR PRODUCER

- Julia Cort

- SENIOR SERIES PRODUCER

- Melanie Wallace

- MANAGING DIRECTOR

- Alan Ritsko

- SENIOR EXECUTIVE PRODUCER

- Paula S. Apsell

A NOVA Production by Little Bay Pictures, LLC for WGBH

© 2013 WGBH Educational Foundation

All rights reserved

This program was produced by WGBH, which is solely responsible for its content.

Image:

- Image credit: (David Pogue)

- Courtesy David Pogue

Participants

- Christopher Baran

- TravelingNuker

- Mike Beller

- Tradeworx

- Sebastiaan Bowier

- Human Power Team

- Carlos Casas

- Google Fiber

- Scott Ferguson

- Oracle Team USA

- Kurt Jordan

- Oracle Team USA

- Dirk Kramers

- Oracle Team USA

- Doug Lawson

- Southwest Airlines

- Jack Levis

- UPS

- Wouter Lion

- Delft University of Technology

- Tom Morgan

- Polytechnic Institute of NYU

- Manoj Narang

- Tradeworx

- Jason Steffen

- Fermilab

- John Wayland

- Plasma Boy Racing

- Peter Weyand

- Southern Methodist University

Preview | 00:30

Full Program

Notice: Undefined index: video_length in /home/nova/zend/application/templates/resources/multi-ep-pro.phtml on line 500

Full program available for streaming through ...

Watch Online

Full program available

Soon

Making Stuff Wilder

Host David Pogue travels the globe to explore new technologies inspired by nature. Airing October 23, 2013 at 9 pm on PBS Aired October 23, 2013 on PBS

Program Description

Transcript

Making Stuff Wilder

PBS Airdate: October 24, 2013

DAVID POGUE: Civilization is built on the human drive to invent. We take the raw stuff of our planet, the materials that give names to the ages, and craft them into new forms, expanding our horizons, exploring hidden worlds and engineering life-changing technologies, always pushing the limits to be colder, faster, safer, wilder!

And now a new era is upon us, as scientists turn for inspiration to the ultimate inventor and engineer, nature. What can we learn from living things to make our own technology even better?

How long before they become self-aware and turn on their overlords?

I'm David Pogue, and I am on a quest for the world's wildest new stuff. From a carnivorous tropical plant,…

Whoa, Little Shop of Horrors.

…to an elephant's trunk,…

A little elephant snot for you.

…there's a revolution underway, as scientists borrow the best ideas nature has to offer…

I feel like an outtake from Ghostbusters.

…and put them to work, creating a robot as big as an ox,…

LS3, get up.

…and just as sturdy on its feet;…

The power!

…even teaching viruses…

I got…aw…

…to make batteries!

Come on!

Nature has been making stuff for billions of years. What happens when scientists open up its toolbox to make stuff wilder?

We humans love to invent. We've been doing it for thousands of years, but how many of our inventions really stand the test of time?

Now,imagine a world filled with only the very best stuff: amazing ideas and astonishing designs, each one the result, not just of years, not of decades, but millions of years of research and testing in an environment where the competition can be ruthless.

Since life began on Earth, it has been innovating, making discoveries in materials and engineering we've only recently begun to appreciate. The hard-won lessons of life on Earth, gained over eons, may help solve our very human problems.

Can forms found in nature reshape our machines, making them more useful? Can we build the agile movements of animals into our robots? Have some of the best ideas for new materials already been discovered by nature? What if we could make things like nature does? Can we grow the electronics and fuels of tomorrow, using the code of life itself: D.N.A.?

The search for answers to these questions has taken some strange turns.

Here at the University of Guelph, about an hour outside Toronto, materials scientist Atsuko Negishi and biologist Julia Herr think that these lovely creatures called hagfish may revolutionize how we make strong materials.

JULIA HERR (University of Guelph): So these are Pacific hagfish. They are well-known for their unique defense mechanism.

DAVID POGUE: So, if I wanted to see this, what would we do? Like, could we poke it with a stick?

JULIA HERR: I think the best way to do it is to reach in there and grab one.

DAVID POGUE: Oh, my gosh. Look at that. Disgusting.

JULIA HERR: There you go.

DAVID POGUE: Oh, no. I've been slimed! I feel like an outtake from Ghostbusters. Look at the quantities of this stuff. This is like three times the volume of the fish. How could all this slime come out of that tiny thing?

It's an impressive display of "slime-ocity." And it works great as a defense. When a gill-breathing predator bites down on a hagfish, it gets a mouth full of slime. With its gills clogged, it becomes more worried about suffocating than eating.

So how does the hagfish conjure all that slime? One of the key components is mucin, a family of proteins that includes, you guessed it, human mucus.

Mucin consists of a protein backbone, with lots of sugar side chains hanging off it, like bristles on a brush. These side chains attract water molecules, soaking them up remarkably well, in fact amazingly well.

Atsuko offers to show me what a little dab of hagfish juice can do.

ATSUKO NEGISHI (University of Guelph): So, this is a beaker of seawater. So, we're going to make some slime.

DAVID POGUE: It's getting a little misty.

ATSUKO NEGISHI: I'm just going to mix it up a little bit.

DAVID POGUE: All right.

ATSUKO NEGISHI: And if you could lift that out.

DAVID POGUE: Look at that. Oh, my gosh, that tiny dab…. Hey, there's no water left. It's taken the entire thing of water with it. That little tiny pea's worth of white stuff…

Would anyone like some? Children, there's plenty to go around.

While the mucin sucks up the water, it's a second component that holds the slime together, so I can pick it up: these threads, visible here.

Both components start out inside pores along the side of the hagfish. The water-loving mucin molecules are packed into one type of specialized cell, while the threads are wound tightly in another kind of cell. When under attack, the hagfish ejects the cells and they break open. The mucin molecules collect water molecules, while the threads, each about six-inches-long, unfurl, binding the mucin into a continuous and disgusting mass of slime.

It's these spider-silk-like threads that have really caught the researchers' attention. They might even serve as a model for a new kind of fiber, because they're surprisingly strong: ten times stronger than nylon, a synthetic material made from petroleum. If we could use hagfish fabric instead, it could help reduce our dependence on oil.

So, what are the steps involved in going from hagfish slime to handsome garments made of it?

ATSUKO NEGISHI: So, the first step would be to be able to artificially make these hagfish slime threads.

DAVID POGUE: It's early days, but Atsuko has been working on a process to create her own fiber, using proteins she's derived from freeze-dried hagfish thread. She mixes the proteins with formic acid and puts a few drops onto a salt solution, then draws up the material to create her own artificial hagfish thread.

So far, it doesn't test as strong as the original, but she has high hopes.

So you started with hagfish fiber. You treated it to come up with this component goop, put it back into saltwater, turned it back into a piece of thread. So you start with a thread, you ended with thread. Why didn't you just use the thread to begin with?

ATSUKO NEGISHI: One of the reasons is because we can't farm hagfish, and so…

DAVID POGUE: You can't farm hagfish?

ATSUKO NEGISHI: They don't currently reproduce in captivity, and so we can't have these big farms of hagfish.

DAVID POGUE: I see. Plus, it'd be a pain to get up at 4:00 in the morning to go milk the eels.

So, all of this thread-pulling is really in anticipation of the day Atsuko can synthesize her own hagfish proteins.

There it is: actual thread made of actual reconstituted fish mucus, the dawn of the era of hagfish fabric, right there.

Hmmm, what would that be like?

Nighttime is the right time for a fabric from the deep: Hagwear. But it's look, don't touch, or the surprise will be on you! Hagwear!

All right, hagfish fabric may not yet be runway-ready, but in the right hands, nature's innovations offer clues that can literally shape the stuff we make. Built to thrive in their environments, animal bodies offer winning designs and possible solutions to our own engineering challenges. After all, feathered wings inspired our metal ones; sleek swimmers helped shape our boats. What other new solutions can be found by studying the forms of animals?

I'm in Stuttgart, Germany, at the Wilhelma Zoo. It might be the perfect place to see the future shape of technology, according to engineer Heinrich Frontzek.

So, when an engineer, like you, comes to the zoo, do you see it differently from regular visitors?

HEINRICH FRONTZEK (Festo): I think so, because we want to get inspired by the nature, and here in the zoo, they're so concentrated, the huge variety of animals, all optimized for that application. And we are thinking in application, so why should…? This is a paradise for an engineer.

DAVID POGUE: Heinrich works for an automation company, trying to improve one of the most important inventions of the 20th century, the robotic arm. It's been revolutionizing factories since the first one was introduced, in 1961, at General Motors.

But robotic arms have some problems. Just like the one on humans, the traditional robot arm consists of rigid parts, joined together, often limiting its programmable motion. They're also dangerous. Get hit by one of these, and it's lights out, so robots often end up behind protective fences, unable to work closely with humans.

The German automation company Heinrich works for, Festo, decided to reinvent the robotic arm, making it more flexible and less dangerous. Heinrich leads me to the source of the inspiration. And it turns out, maybe, the best arm is a nose.

So why would you look at an elephant's trunk and think this would help you with automation?

HEINRICH FRONTZEK: As you can see, it's so flexible and transmits a lot of force and makes it much more easier to handle things. And this is our business, handling things, pick and place, to automate factory or process, and it makes sense to look into nature and to get inspired by nature, and the elephant is an excellent ambassador for that.

DAVID POGUE: Thanks to Zella, a 47-year-old Asian elephant, I get a little first-hand experience with what an elephant packs in its trunk.

Little elephant snot for you.

An elephant trunk is an impressive multi-tool, able to slurp up water…

ZOOKEEPER: Now she collects the water.

DAVID POGUE: …and squirt it.

Breakfast is on.

It picks up food like a vacuum cleaner, manipulates objects, and it's strong. Zella can use her trunk to lift over 400 pounds.

No, no, that's my wrist.

She could crush me like a bug, couldn't she?

ZOOKEEPER: Yes, yes, sir.

DAVID POGUE: Here, have some more peanuts.

But the trunk's most impressive attribute is its amazing flexibility. It comes from having no bones, and about 40,000 muscles, arranged lengthwise and in rings. With no bones and no joints, it's about as far away from a traditional robotic arm as you can get.

Beep! Beep!

I head to Festo's headquarters, in nearby Esslingen, to see their version of the elephant trunk. They call it a "bionic handling assistant."

Now, this looks like a bionic handling assistant.

HEINRICH FRONTZEK: Yeah. You're absolutely right. This is our trunk.

DAVID POGUE: Festo's version of the trunk is made of plastic, with a series of air chambers inside. Filling different parts with compressed air causes it to bend.

So if I wanted to bend it that way?

HEINRICH FRONTZEK: We need a tube with compressed air for this expansion and then you get this bending to the other end.

DAVID POGUE: So this blows up like a balloon?

HEINRICH FRONTZEK: Yes, for sure.

DAVID POGUE: They're testing the assistant with this simple motion, for use in a packaging operation.

Look at that, it tucks it in nicely. Well done, Dumbo.

But it is inherently more flexible than a conventional arm, and, just as important, far safer.

HEINRICH FRONTZEK: We don't have electricity, we don't have steel and iron and all this masses, which are…could damage a person. It's a weight of five pounds. Some valves, a little control system…

DAVID POGUE: So there's really nothing here but plastic tubes and air.

HEINRICH FRONTZEK: Yeah.

DAVID POGUE: Does it do tricks?

In this application, the tip of the trunk works by suction, but Festo has experimented with what it calls a "fin gripper," inspired by fish fins.

If you push on the middle of a tail fin, it doesn't curl away from you as you might expect, it curls toward you, giving a fish much more efficient strokes. But Festo has built that principle into a gripper that curls around the object it needs to pick up, adapting to the shape.

HEINRICH FRONTZEK: When we have to change the shape of the products we are handling, so, we need something flexible, more flexible. For this, it is very helpful to use a fish tail as a gripper.

DAVID POGUE: So, it looks to me like you're about to demonstrate how this might work.

HEINRICH FRONTZEK: Yes. We have two different gripping devices. One with a fish tail, and this is a traditional one the robots are using.

DAVID POGUE: Can I see these things close?

HEINRICH FRONTZEK: Sure. Same pressure, everything is equal.

Now, we will see what happens. This is the old robot, and this is the bio-engineered method.

DAVID POGUE: Okay. Let the competition begin.

Look at that! Traditional robot hand, shattered to smithereens, and the fish tail gripper really did its job. So you have robot, zero; fish tail, one. You have stolen from nature and did a great job.

HEINRICH FRONTZEK: Thanks.

DAVID POGUE: Thank you very much. Oops! They'll edit all this out.

Combining the fin gripper with the elephant trunk produces a flexible, lightweight and safe robotic arm, ready for all sorts of applications.

HEINRICH FRONTZEK: Biomimicry, nowadays, it's part of the design process here at Festo, so everybody is using this cross-thinking, get inspired by nature and to transform these ideas into industrial applications.

DAVID POGUE: May I? Thank you.

Festo's handling assistant steals its form from the elephant trunk, but Festo isn't alone in adapting designs found in nature and applying to them to industry. The beak of the kingfisher bird breaks the water with very little resistance, inspiring the shape of this Japanese bullet train, so it would cut efficiently through the air. The shape of the yellow boxfish provides a rigid structure, and has very little drag for such a large volume, all reasons Mercedes-Benz used it for the design of a high-efficiency concept car.

But making machines that look like animals is one thing, what about making machines that move like them?

For thousands of years, when we've invented new forms of transportation, many have been based on a human insight not found in nature at all, the wheel. But there are plenty of places wheels can't go, even ones wearing a belt of tank tread.

The inability of our machines to traverse difficult terrain has dire consequences on the battlefield and in search and rescue. But while wheeled vehicles struggle off-road, there are some creatures getting around on legs. That's had engineers wondering, "What lessons can we learn from animal movement? Can we give our machines a leg up?"

Walking is easy for animals; even a toddler can do it.

C3PO/STAR WARS: Excuse me, sir.

DAVID POGUE: And, thanks to movies, creating walking machines seems easy, too. Just look at C3PO from Star Wars…

C3PO/STAR WARS: C3PO: Oh! Nice to see a familiar face…

C3PO/STAR WARS:

OTHER BOT: It Chuta.

C3PO/STAR WARS: C3PO: How rude!

DAVID POGUE: …or its walkers. You'd think the problem's been solved, but in real life, it's hard. One of the best-known early attempts at a walking machine is General Electric's walking truck, from the '60s. It even tackled uneven terrain, but it took a human operator to decide where to place each foot, one at a time, an exhausting task.

By the '70s, computer control automated the walking motion in a series of crawlers, built around the world, though they werestill driven by human operators. These kept a tripod of legs on the ground, maintaining stability at all times, a system called "static balance." They moved slowly, like a walking table.

But in the 1980s, a very different approach gained ground.

I've traveled to Massachusetts, to visit a company that builds robots based on that work. The company's founder, Marc Raibert, has been building walking robots for over 30 years. Early on, he steered away from the static balance of walking tables.

To help me understand how he views animal locomotion, he invites me to take a ride on a pogo stick. It's tricky, because, like all standing humans, I am top-heavy; in technical terms: an inverted pendulum.

MARC RAIBERT (Boston Dynamics): Here is a normal pendulum, right? If you swing it…

DAVID POGUE: The weight is at the bottom. Yeah.

MARC RAIBERT:But if you put the weight at the top, what happens? If you don't do anything, it tips over, but if you move the point of support, you can keep it balanced.

DAVID POGUE: If you're top-heavy, staying balanced requires keeping your base of support under your center of gravity. That's what Marc is doing by shifting the bottom of the broom as it tips; that's what I'm doing by moving around the pogo stick, and that's what all of us do, all the time, when we're upright.

In fact, the human brain receives constant updates to maintain the body's balance: from the inner ear, where a series of fluid-filled canals send signals about the position and motion of the head; from the eyes, which send signals about the body's position relative to other objects; from internal sensors that tell us about the position of body parts relative to each other; and from external pressure sensors in the hands and feet, that send signals about the source of support, for example, if you're on uneven ground. All of this information feeds into our cerebellum, which keeps our top-heavy body from tipping over, even when we're just standing around.

Without it, you would topple over.

To Marc, we are less like a static table and more like a pogo stick. To focus on the problem, he built a robot that had only one springy leg. It constantly calculated where its weight needed to shift to stay upright, very pogo-stick like.

Even when he added more legs, he kept the bounce in their step, and an active sense of balance.

For the last few years, Marc has been applying what he's learned to solve a problem for the U.S. military. On rough terrain, wheeled vehicles aren't much use. And soldiers often haul everything on their backs, leading to injuries and exhaustion. Marc invites me to see Boston Dynamics' solution, out at a nearby park.

Meet LS3, also known as AlphaDog. It's designed specifically for rough terrain, anywhere a soldier might go on foot, and it carries 400 pounds of gear, along with enough fuel for a 20-mile mission.

MARC RAIBERT:So, Dave, in this mode, the robot is following the leader. He's got a backpack on and has some reflective stripes on it, and the vision system focuses on that and looks at them, and then it records what path he takes through the terrain.

DAVID POGUE: Is it modeled after a particular animal, an ox or a horse or…?

MARC RAIBERT:You know, not really. We take inspiration from how animals are designed and how they're implemented, but then we have to use human engineering tools, in the end, and human materials, so sometimes it stays like the animals, sometimes it departs.

DAVID POGUE: I ask Marc for a tour of LS3, of course, after it's been shut off.

MARC RAIBERT:So this is the leg, and it's got a muscle here, or the actuator, which causes it to move. This muscle moves the knee joint. The computer is really the equivalent of a laptop-style computer. So, you know, all the balancing is done in that computer. All the speed control, all the turning is done in that computer.

There is a laser range-finder here that provides 3D-depth information. There is a set of cameras here that are used to track a human leader. There's other cameras under here that look right in front of the robot and provide information about the shape of the terrain,…

DAVID POGUE: Wow.

MARC RAIBERT:…so that the feet can pick the best places to step.