Engineering Ground Zero

Designing and building One World Trade Center and the National September 11 Memorial & Museum Airing September 11, 2012 at 9 pm on PBS Aired September 11, 2012 on PBS

- Originally aired 09.07.11

Program Description

Transcript

Engineering Ground Zero

PBS Airdate: September 7, 2011

NARRATOR: It will be the tallest building in America, a decade-long project to transform tragedy into triumph. To build it, engineers will have to push materials to their limits:...

JEFF HOLMES (Project Coordinator, Tishman Construction): There's 215,000 cubic yards of concrete, 45,000 tons of structural steel; those quantities of material, to build this one building, you know, I get a kick out of that.

NARRATOR:...concrete, glass and steel made stronger than ever before.

This isn't just any construction site. This is Ground Zero, the site of the worst terrorist attack on American soil. After years of controversy, false starts and delays, a new kind of skyscraper is taking shape here.

DAVID CHILDS (Lead Architect, One World Trade Center/Skidmore, Owings & Merrill, LLP): It is very important that we did rebuild. It gave us a chance to rebuild better.

NARRATOR: Renowned architect David Childs must make a tower for the future: beautiful, green and, above all, safe.

MICHAEL BLOOMBERG (Mayor of New York City): Anything you do in an iconic city, potentially, is a target. Iconic buildings, they're also symbols to us that we have something to be proud of.

NARRATOR: Next door, an equally daunting challenge faces another architect. In the footprints of the Twin Towers, Michael Arad designs a memorial to honor those who lost their lives on 9/11.

MICHAEL ARAD (Architect and Designer, 9/11 Memorial): I want to make it a living part of the city again, without erasing the past, without forgetting.

NARRATOR: But his vision has a deadline.

RONALDO VEGA (Director of Design, 9/11 Memorial): Nothing matters, until we open this on the 10th anniversary. If we don't get it open on the 10th anniversary, it's all for nothing.

NARRATOR: Will the 9/11 Memorial be done on time? Will One World Trade Center be the icon its creators hope for? Engineering Ground Zero, right now, on NOVA.

Just after midnight, a flatbed truck arrives in New York City. It's carrying a 35-ton beam, a small piece of a massive puzzle taking shape in downtown Manhattan; its final destination: Ground Zero, where the Twin Towers collapsed in the worst terrorist attack in American history.

Now, almost a decade later, this 16-acre site bustles with construction, as One World Trade Center rises, soon to be America's tallest skyscraper.

PAUL GOLDBERGER (Architecture Critic, The New Yorker): Going back into the sky is really important, because that was something that was taken away. And I think it's appropriate to put it back, to show that the life of the city goes on and is more powerful than the forces that attacked it.

NARRATOR: On a mild winter's day, the 35-ton steel beam that arrived the night before is hoisted into position. It's just one of thousands of difficult and dangerous jobs construction workers are tackling here, as this enormous 16-acre site is rebuilt. But to get to this point took years of bitter debate over what should be done with Ground Zero.

GEORGE PATAKI (Governor of New York State, 1995–2006): Everyone had a different idea and a different vision of what should happen there. Some important figures didn't want any memorial, wanted the whole thing redeveloped. Others said, "You can't develop anything down there, it all has to be preserved." So pulling everything together was, was not an easy task.

NARRATOR: After many frustrating false starts, a plan came together, and the hard part of building it has now begun.

MICHAEL BLOOMBERG: This is one of the most complex engineering challenges because of the size of the site, and everything is built over and over and under and next to and connected. You ever try to build a building around a railroad? Not easy!

CHRIS WARD (Executive Director, Port Authority of New York & New Jersey): This is a once in a lifetime, once in a generation, once in the history of the United States project. This is about fundamentally rebuilding an entire downtown and creating a new city within a city.

NARRATOR: When complete, the site, in lower Manhattan, will include a train station to rival Grand Central, six new towers, and, at its heart, the 9/11 Memorial, built in the sacred footprints of the original Twin Towers.

PAULA BERRY (Board Member, 9/11 Memorial): What people will walk away with, no matter what, now and in the years to come, is they'll understand—I hope they'll understand—the magnitude of the event.

NARRATOR: The Memorial will help us look back and remember those who died in the attack, and right next to it, a skyscraper that its creators hope will become an architectural icon, One World Trade Center, will help us look forward.

The challenge of building this new tower begins with world-renowned architect David Childs, who is putting his reputation on the line. Can he come up with a design that reflects the importance of this site? Can he satisfy the safety demands of a building that could easily be a target again?

DAVID CHILDS: There are all sorts of levels of achievements that you want to have with the building. If you write them all down, as I did at that time, you are overwhelmed. You thought, "How do I ever get all of this together?"

NARRATOR: It comes together in a design that is a conscious attempt to balance security with beauty. By pushing basic building materials—concrete, steel and glass—to their limits. The first 20 stories are like a bunker, built to withstand the force of a truck bomb. As it rises, the tower transforms into eight interlocking triangles, covered in huge panels of crystal clear glass. More than a hundred stories up, a broadcast antenna brings the total height to a symbolic 1,776 feet.

With a price tag of more than three billion dollars, Childs' design will be one of the most expensive skyscrapers ever built and one of the most innovative.

DAVID CHILDS: We needed to investigate and invent new ways to show how buildings could be built in the future. If we were trying to do this 50 years ago, we would not have had the technologies to be able to do this building.

NARRATOR: Almost 50 years ago, the most innovative towers of the time were being built at the World Trade Center site.

The original Twin Towers employed a unique state-of-the-art steel structure that allowed for wide open floor spaces, where up to 40,000 people could work each day. But decades after completion, these marvels of engineering proved vulnerable in a way no one had foreseen.

Childs watched the events of 9/11 unfold from his office in downtown Manhattan, where, at 8: 46 a.m., the North Tower was struck by an airplane.

DAVID CHILDS: I remember walking up to a window, and a young man turned to me with tears coming down his face. And he said, "Will they fall down?" And I said, "No," right away. Because I knew that if they hadn't been knocked over, they wouldn't fall down. The fire would be put out. Never has a steel-structured building, in the history of steel-structured buildings, ever fallen down for reasons of fire.

NARRATOR: Also watching, but from a more dangerous vantage point, was David Berry. He was in the South Tower.

PAULA BERRY: They had come on the loudspeaker and said to stay in the building, and for good reason. They were in the South Tower, and stuff was coming out of the North Tower. They had no idea what was going to happen in the South Tower.

NARRATOR: Then the South Tower is hit. Both buildings are in flames, but these are no ordinary fires. They are as hot as 1,800 degrees, hot enough to weaken the steel structure.

Inside, people try to flee the building, down smoke-filled staircases. As they do, rescue workers try to push their way up. At the point of impact, the emergency staircases are compromised. Nearly 2,000 people on the floors above are trapped inside, with no escape.

PAULA BERRY: Those people who didn't leave early got stuck, particularly in the South Tower and particularly where he was; he was on the 89th floor. So, you know, they were stuck.

NARRATOR: The North Tower stands for an hour and 42 minutes, the South Tower, for 56 minutes. Finally, the steel structure gives way to the heat, the floors start to sag, the perimeter steel columns snap. The Twin Towers do the unthinkable: they collapse. Nearly 3,000 people die.

The unimaginable becomes a new reality that David Childs must face. To build a tower that is strong enough to withstand catastrophic events and save lives. Along with a team of architects and engineers, he must rethink strength and safety from the inside out, starting at the core.

The core of a skyscraper is a backbone that runs up the center. It provides structural support and strength. The core of One World Trade Center also contains critical safety systems like extra-wide stairwells. And it's made of a material that's strong, like steel, but more fire-resistant: concrete.

DAVID CHILDS: The outside of the core, this whole center spine of the building, is of concrete.

NARRATOR: The cores in the Twin Towers were compromised on 9/11, because they were made of steel wrapped in thin sheetrock.

DAVID CHILDS: Where the planes hit, that sheetrock was not strong enough to take that punching sheer, which, of course, concrete is.

NARRATOR: With its high compressive strength, concrete can resist impact in a way that sheetrock can't. Childs' design calls for super-strong concrete, so strong it means going back to the lab to develop it.

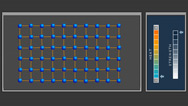

CAS BOGNACKI (Engineer, Port Authority of New York & New Jersey): This is a concrete specimen that will be used for Tower One at the World Trade Center. If you could set this cylinder and put a platform on it, you can accommodate a thousand Americans standing on this cylinder, you know, normal people, 175 pounds in weight. A thousand people can be supported by this four-inch-diameter cylinder.

NARRATOR: Concrete is made of sand, stone and binding agents, like lime or cement, that, when water is added, hold the mixture together. But the recipe can be revised by using less water, replacing it, instead, with chemicals that keep the concrete moist without reducing its strength.

CAS BOGNACKI: Water makes this concrete move in place. But you can't have too much water, 'cause when you have too much water, the strength goes down.

NARRATOR: The goal: to make concrete that can withstand loads of up to 14,000 pounds per square inch. Normal concrete is about 5,000 p.s.i. Even the Hoover Dam is no more than 7,500.

But strong concrete has its own challenges. Before the recipe is ready for One World Trade Center, it must be tested under real-world conditions where it's mixed by the ton. The stronger the concrete, the harder it is to move. When concrete spreads too far, it's got too much liquid, a sign that it's lost strength. If it doesn't spread enough, the concrete is too thick and will be impossible to pump hundreds of feet up the building before it sets.

JOHN ABBEY (Collavino Construction): Right now, the mix is still extremely sticky, and I think once we multiply it with 30, 40 stories, it will not comply to our needs.

NARRATOR: As the crew tweaks the recipe, they adjust the amount of water and chemicals until, finally, after two days, they get it right.

CHARLIE WOZNICK (Collavino Construction): If we didn't do this today, and we actually just said, you know, "Let's ship it to the job and give it a shot," it would have been a disaster.

NARRATOR: Twice a week, around 1,000 tons of concrete are mixed and dispatched to One World Trade Center. It is always a race against time. Driver Eric Szemple has only 90 minutes before the concrete starts to harden.

ERIC SZEMPLE (Collavino Construction): Concrete, it's a perishable item. We have, like, an hour and a half to get the load off.

NARRATOR: Along the way, his mixer keeps the concrete moving. Once he arrives on site and offloads his cargo, crews have less than an hour to pump it through an elaborate system of hoses, where it is poured into a mold and secured with steel bars, called rebar, that give the concrete something to latch onto.

SAL MERLINO It's strong. That's why I call it "liquid steel."

NARRATOR: When finished, One World Trade Center will contain almost 500,000 tons of this liquid steel, much of it in its core, which has walls up to six feet thick. Inside, the core protects a total of 70 elevators, as well as the extra-wide stairwells that are pressurized to keep smoke out.

DAVID CHILDS: When a door is opened, that pressure goes out, keeping the smoke away from it. And that's a very effective thing. Smoke is the real killer.

NARRATOR: All these life safety systems are there for one reason: to avoid the tragedy of 9/11, where two-thirds of the victims died because they couldn't get out of the building.

And nothing will remind us of this loss so poignantly as the 9/11 Memorial next door. The 9/11 Memorial is the vision of another architect who witnessed the events of that day.

MICHAEL ARAD: I remember that day very clearly. It was very, um, surreal. And there was a sense of utter destruction and chaos.

NARRATOR: On September 11, 2001, Michael Arad watched the towers fall from the roof of his apartment. In the days and weeks that followed, he mourned with everyone else, going to the places where people gathered.

MICHAEL ARAD: The experience that, for me, was most poignant was actually, late one night, coming to Washington Square Park and finding a group of people standing around that central fountain. I think people came there alone, but when they were there, standing around that fountain, they were, and I was, we were together. And, I felt one with the city and with everyone else around me, in a way that I had never felt before.

NARRATOR: When a competition to design a 9/11 Memorial was announced, Arad knew exactly what it should be:...

MICHAEL ARAD: It was an idea that was just in my head and then on a piece of trace paper, and then, eventually, I ended up building a small fountain on my rooftop.

NARRATOR:...two pools in the footprints of the original towers. It was a design that spoke to jury members, who chose it out of 5,000 entries.

MICHAEL ARAD (Archival Footage): I'd like to thank the jury members for having confidence in me and selecting my design.

NARRATOR: Paula Berry was on the jury. Having lost her husband on 9/11, she helped represent the families of those who died.

PAULA BERRY: It had a very solemn, sacred feel to it. It's a place which really does convey the absence of something and the voids.

PAUL GOLDBERGER: Using the footprints of the two towers as the starting point for the Memorial is actually very powerful symbolism. Where there was presence, there is now absence; where there was solid there is now void.

MICHAEL ARAD: This is actually the model that I presented to the jury back in 2003, and it's starting to show its age.

NARRATOR: Now, the challenge is to get from concept to construction...and fast.

CHRIS WARD: The Memorial, under earlier construction schedules, wasn't going to be done until 2013, and that was clearly unacceptable.

NARRATOR: Chris Ward is the executive director of the Port Authority of New York & New Jersey, the government agency that owns and manages the site. He assumed his post in 2008.

When work began on Ground Zero, the plan was to build from the bottom up, starting some 80 feet below ground level where extensive damage had to be repaired and the foundations laid for the many structures that would someday occupy the site.

The Memorial was only one of those structures.

CHRIS WARD: We quickly realized the size and the dimension of the project was so large it was almost, it was almost unmanageable, because you had no real sense of priority. And that was really what was hindering the site. And once we decided that the Memorial would be our goal, you had to completely change everything about your construction strategies and how you attack that one problem.

NARRATOR: Ward enlists a team of engineers to create a plaza at ground level first and build the memorial pools down into it. It adds hundreds of millions of dollars, but shaves two years off the schedule—a critical decision to meet the one deadline that cannot be missed: September 11, 2011, the 10th anniversary.

MICHAEL BLOOMBERG: We just have to have a memorial done on the 10th anniversary. That's not a wish, that's an obligation.

PAULA BERRY: The 10th anniversary is probably the most important one, certainly to the family members, right? So, we need it as a means and as a marker.

JOE DANIELS (President and Chief Executive Officer, 9/11 Memorial): The eyes of the world, the entire world, will be fixed on Ground Zero to get this Memorial open and dedicated on the 10th anniversary. However, the actual construction, it's going to be close. Success is not built in.

NARRATOR: At the Memorial, from now on, every day counts. Ronaldo Vega supervises construction at the Memorial. He's been on site since 9/11, first to help in the cleanup, and now to make sure the Memorial is done on time.

RONALDO VEGA: We've just got to get it built, and we're on a tough time schedule, and we need to finish this on the 10th anniversary. That means we may be putting in double and triple shifts to get it done.

That panel that's coming down is going to be set into place with two anchors from the bottom. It slides into the slots that are at the top and the bottom, and the next piece will lock it into position.

NARRATOR: With the plaza in place, the memorial pools are ready to be lined with granite, cut from a quarry in Virginia. Almost 5,000 tiles must be laid in a specific order, so there is a continuous pattern to the grain.

RONALDO VEGA: Just look at that stone. If you could just imagine the lines not being there, it looks like one stone. Look at how that grain just flows. It's almost as though this stone is a continuation of this stone. The adjacent piece looks like it belongs next to it.

NARRATOR: Each of these pools is 30,000 square feet, almost an acre of void.

MICHAEL ARAD: It's, you can really feel it in your chest: the presence of absence here.

NARRATOR: But this is just the beginning. The design calls for 52,000 gallons of water to cascade over the walls every minute, drop 30 feet, and disappear into a second, inner pool. But executing this plan is deceptively complex.

CHRIS WARD: Fountains sound simple; they're not. They're such a combination of the sublime and the beautiful, but they're also, you know, powerful engines of pumping, you know, 600,000 gallons of water, day in and day out. And we're doing two of them.

MICHAEL ARAD: We didn't want to create a torrent. This is not about being behind Niagara Falls. It was always about creating something that is gentle yet persistent.

And then the question is, "How do you make that idea take shape?"

NARRATOR: The solution arrives on site. It's called a weir. Weirs are normally used to alter the flow of rivers to prevent flooding, but here, they need to move water into the shape of an architect's vision. The weirs are there to push it outward just far enough to give it a gentle arc, to make it fall in a neat cascade. Each weir has to be leveled to within a sixteenth of an inch.

MARK CILLA (Fresh Meadow Mechanical Corp): If it's not leveled, then the water will go more over one spot than another, and it won't look right. So that's why it's got to be dead-leveled.

NARRATOR: Underground, an elaborate system of pumps and pipes will send the water up to the weirs.

LOU MENDES (Supervisor, 9/11 Memorial): Those are the pumps that supply the water to the upper trough.

NARRATOR: The entire system is filled with New York tap water, which will be recycled.

LOU MENDES: Those are the headers that act as the return from the pool.

NARRATOR: A series of filters keeps the water clean.

With the weirs in place, the most important test is ready: it's time to turn on the water. Workers carefully watch as water starts to flow through the system into the troughs by the side of the pool.

ALFREDO JIMENEZ: Things are holding pretty good, so we're going to go ahead and, uh, and let it go over.

WORKER: Let's get it over the top right now.

WORKER: Okay.

ALFREDO JIMENEZ: It's coming over there.

WORKER: It's starting to go over here, too.

ALFREDO JIMENEZ: Yeah, yeah, that wall. The wind, the wind is doing it.

WORKER: Oh, yeah, there it goes.

NARRATOR: After years of preparing, the test is a glimpse of what the memorial pools will finally look like.

MICHAEL ARAD: The idea of creating this angled weir that would project the water forward four to six feet, as it falls 30 feet, allowed us to create this beautiful visual effect of the water, almost like a billowing curtain.

It's beautiful. It's moving. I, um, am at a loss for words.

NARRATOR: The footprints where the Twin Towers once stood are starting to take shape as the heart and soul of Ground Zero. But the countdown to the 10th anniversary is on and there is still a lot to accomplish.

RONALDO VEGA: Nothing matters until we open this on the 10th anniversary. If we don't get it open on the 10th anniversary, it's all for nothing. We have to get it open on the 10th anniversary. And every day, every hour we're fighting for that.

NARRATOR: Next door, at One World Trade Center, the challenge is different. People still wonder, "Should it be built at all?"

T.J. GOTTESDIENER (Managing Partner, Skidmore, Owings & Merrill, LLP): After 9/11, there was a cry, and there was a reaction that people said, "We're not going to build tall towers anymore." But skyscrapers have a very important urban responsibility: they bring people together in a close, coordinated, dense environment where people need to and want to be close to each other.

NARRATOR: But does such a dense environment invite another attack at Ground Zero?

David Childs must protect against it, especially at the base of the building.

CHRIS WARD: The terrorist models lend themselves to the idea of truck bombs, lends itself to large explosive devices getting to the site and threatening that tower.

NARRATOR: A security review pushed Childs to design a one-of-a-kind structure called the podium. It makes up the entire base of the building, 200 square feet wide by 185 feet tall, nearly one-fifth of the tower. Built with thick walls of concrete, reinforced with enormous steel columns, the podium is strong enough to protect the base from the impact of a massive truck bomb.

But creating a fortress is not the message Childs wants to send.

DAVID CHILDS: The initial worry that I had is that I didn't want to have this appear to be a "concrete bunker," as the phrase was used.

NARRATOR: In an attempt to make the podium more inviting, he designs soaring entryways. Behind them, giant concrete blast walls protect the lobby, but Italian marble will hide their true purpose, and large openings will allow sunlight to stream in.

DAVID CHILDS: Because of the nature of the destruction that was here before, you don't want to give the impression that this is a place of refuge and of fear. You want it to be a sense of openness to it. This building needs to appear open.

NARRATOR: He comes up with a novel and risky idea: surround it with glass, but not just any glass, prismatic glass that reflects the sun during the day and emits light at night.

DAVID CHILDS: So the base of the building can in fact emanate light. It's that kind of sense of mystery that light can really bring to a building, make it something that you want to walk towards and be engaged with, and being welcomed to it.

NICOLE DOSSO (Architect, Skidmore, Owings & Merrill, LLP): We're always looking to try to come up with unique ideas and unique forms, and I think there was this idea of coming...of, kind of, creating this kind of jewel box, this sort of refraction of light you got from using a prism.

NARRATOR: It's a delicate effect, but to take its place at the base of the building, the glass must be super-strong. No one knows if those two goals can be achieved at the same time.

JEFF YIGDALL: (Engineer, PPG Industries): We have spent, now, several years developing and adapting our equipment, in order to meet what was originally an architect's concept. This concept being this one-inch-thick glass, etched out into a pointed pattern, for reflection, and then laminated to make a very thick, extremely strong barrier glass. And while this was a great concept, the challenge to us was that this had never been done before.

NARRATOR: This company specializes in making strong yet clear glass, the kind used in airplanes, military vehicles, even armored cars, but for One World Trade Center there's a critical difference: size.

JEFF YIGDALL: This glass is one-inch-thick glass, 130 inches wide and 159 inches long. Each individual piece of glass is 1,800 pounds, almost a ton of glass in one single piece.

NARRATOR: To create these one-of-a-kind panels, they start the old fashioned way: take sand, combine it with other ingredients, like lime and baking soda, and put it in a furnace at temperatures nearly 3,000 degrees. The intense heat turns the mix into liquid, which is then poured onto molten tin.

The glass appears as a red line floating on top.

On rollers, on a line almost a quarter of a mile long, the glass cools, strengthens and takes on its shape. At the end, it's cut into large 1,800 pound panels.

But it doesn't always work. Sometimes the glass shatters, revealing weaknesses caused by uneven cooling.

JEFF YIGDALL: You can hear that glass in the background just going down.

Even though we look at this as a momentary disaster, in our process, that told us what we need to do to make the correction, in an engineering sense. So this glass will now get totally recycled, re-melted.

NARRATOR: They need to melt it down and start again, adjusting the heat so, inside and out, the glass cools more evenly.

But even when it's finished, this is just the start of the journey. Next, these enormous panes of glass are placed on ships and sent halfway across the world. Weeks later, they arrive in the town of Daya Bay, in southern China, where glass can be cut more cheaply. Using the giant panes made in Pennsylvania, they will try to create prismatic glass at full scale.

Cutting grooves into glass this thick and this large has never been done before. The only way to do it is to build a new machine from scratch.

Its three wheels grind the glass while another three smooth out the grooves. Now the cut glass is laminated to another giant pane to make it extra thick. But will it hold up?

For such a high-tech product, the test is simple and revealing.

ALAIN LAPIERRE: Three, two, one.

NARRATOR: It's not surprising that it breaks, but it's designed to stick together like safety glass.

ALAIN LAPIERRE: Three, two, one.

NARRATOR: Instead, these panes break into dangerous shards.

ALAIN LAPIERRE: As you can see, the debris are pretty big. Something like that would fall on your head, that would not be pleasant. This is why we do these kind of tests.

NARRATOR: When the results of these tests reach New York, the news is heartbreaking. This building is David Childs' legacy. He spent years on an idea that may never see, much less reflect, the light of day. If he can't fix this problem, a solution may be imposed on him, compromising his vision of a perfect blend of security and beauty.

But above the podium, Childs is getting much better results. One World Trade Center is growing, going up a floor a week. Inside, there is a steady rhythm of work: build out the floors with concrete, spray with fireproofing, lay elevator tracks in the cores.

PHIL DUCATELLI: All the way to the very top.

NARRATOR: As the building moves upward, it starts to take on its own distinctive shape.

JEFF HOLMES: A lot of times, you know, older buildings would be a box. This, here you have a square becoming an octagon, an octagon, a different octagon, all the way up until it's a square again, rotated, at the top. That's harder to build than a box.

NARRATOR: The podium of One World Trade Center is a square about the size of the original towers. But as it rises above its base, at the 20th floor, the corners taper in. A square becomes an octagon. Four sides become eight interlocking triangles. Finally, at the top, it resolves in a square once again.

DAVID CHILDS: The profile, as you look from the Memorial, is identical to the old, but, as you walk around it, you see the corners tapering in. It's a new, modern building, but it has a memory of what was lost.

NARRATOR: To achieve this subtle shape shift, Childs turns to steel, 45,000 tons of it.

DAVID CHILDS: Steel is relatively light. It's flexible. You can do all sorts of things with it. It's supple. It's a wonderful material.

NARRATOR: Almost one quarter of it—10,000 tons—starts here: Coatesville, Pennsylvania.

One World Trade Center is designed to be a certified green building. Steel contributes to that, because much of it comes from recycled materials like old refrigerators, cars, even toasters, all melted down into liquid.

Then it's poured and molded into giant sheets.

DUANE GRAVENO (ArcelorMittal USA): It's kind of like working a piece of pizza dough, where you want it to stretch one way and stretch the other way, so that the grain structure are all worked evenly, to get the proper strength that they need for the steel.

NARRATOR: The sheets are carefully cut, welded and shaped to make pieces that fit in a specific place in the building.

Some of the largest are called nodes. They can be as large as 60 tons and stand three stories high. Nodes are giant joints that hold multiple pieces of steel together. They come in all shapes and sizes and make it possible for the building to shift form, from four sides into eight. And they also help re-distribute the weight as the building rises.

Back at the site, a critical node is ready to be hoisted into place.

PETER JACOBS (Ironworker, DCM Erectors, Inc.): Get it up there, closer to the rig.

NARRATOR: Working with steel this big takes experience. Peter Jacobs is a member of the Mohawk Nation, famed for their work on skyscrapers and bridges for over a century.

His work starts at the base of the building, where he moves giant crane hooks, called chokers, into place. Two cranes lift the massive 40-foot-high node hundreds of feet up, where it's now connected to the building.

PETER JACOBS: It's a dangerous job, connecting, very. It's the most dangerous job out of all of them. If you ain't got the heart,.... That's the whole key, right in there.

NARRATOR: But all this steel will soon be invisible, hidden behind panels of glass called the curtain wall. Today, the first piece of that wall arrives.

NICOLE DOSSO: This is the first piece of architecture that's being installed at the Tower One site. It's a really big moment.

NARRATOR: Each glass panel consists of laminated safety glass on the inside, an insulating air space, and another thick pane of glass on the outside, lined with an energy-saving coating. The coating lets sunshine in while reducing heat, resulting in cost savings in office lighting and air-conditioning.

Installing these panels is a painstaking task: they can weigh up to 5,000 pounds.

FRANK COLLETTA (General Foreman, Benson Global): For the last three years, they've been looking at how it's going to fit, but until you get it in your hands and see how this jigsaw is going to fit together, you really don't know what's going to fit and what's not.

NARRATOR: The crew moves the panel into place slowly and carefully.

FRANK COLLETTA: The curtain wall is a little bit different than what you do with the steel. It is a little more precise. It takes a little bit of time.

PETER JACOBS: When it comes to putting up iron, there's a time to be finessing it and there's a time to be giving it. Raising gang guys, generally, we usually just give it. That's the difference between us and them.

NARRATOR: Several hours later the finessing and adjusting pays off.

BRIAN O'FLATERY: We got all three panels up, plenty of daylight left. We had a good day today. We're on number three, and there are something like 13,000 panels. So, we've got a ways to go, still.

NARRATOR: When this wall of glass is complete, it will wrap around the entire building from the 20th floor to the top. It will make the building impermeable to the elements, yet part of its surroundings. Finally David Childs' vision is beginning to take shape.

DAVID CHILDS: We wanted to create a building that was open, welcomed people to that skyscraper form, and you also need to think about its symbolic value. It's the marker in the sky of the most important building down here, which has no height, which is the Memorial, itself.

NARRATOR: The Memorial is also making progress. The pools are formed, the fountains are working, but the most delicate task remains: to make sure this site honors those whose lives ended here and helps future generations remember the past.

In a rarely seen hangar in New York's J.F.K. Airport, that past is being carefully preserved. In twisted steel and broken beams, the full scale of what happened on 9/11 can be witnessed. In smaller pieces—chairs, computers, a handful of bicycles—the human loss of that day is felt. Many of these objects will be part of a massive underground museum being built beneath the Memorial plaza.

RONALDO VEGA: They're going to be looking up at the underside of the plaza above, which is 60, 70 feet above us, so you'll have a very large volume of space. People are going to understand the enormity, the scale of it, of what was lost here that day.

NARRATOR: On these bronze panels, powerful water jets engrave the names of the 2,982 individuals whose lives were lost. But even this is far from simple.

MICHAEL ARAD: How would names be grouped? What would be the logic of the arrangement? How would they be displayed? How would you find a single name, and what would be the significance of finding that name at a certain point?

NARRATOR: The names are not listed alphabetically, but by the locations where individuals died: the South Tower, the North Tower, Flights 11, 93, 77, 175 and the Pentagon. First responders and those who died in the 1993 attacks are also grouped together.

PAULA BERRY: It, in essence, does tell the story of what happened, largely by the way in which the names are arranged. So when you go you will actually be able to sort of peel back and understand the story a little better.

JIM MORETTI (President, Service Metal Fabricating): Fifty percent of the folks that are on the Memorial, no remains were found, and so this is going to be, for many families and many loved ones, the place that they will go on those special days: the birthdays, anniversaries. Unfortunately, this is their final resting place.

FRANK ANDOLINO (Service Metal Fabricating): It's heartbreaking, really, to look at all these people and the pain them and their families endured. It's sad, it really is. But we've got to get a job done, so, we'll get it done.

NARRATOR: As 152 bronze panels are carefully etched, 70 miles away, about 400 trees are being prepared to be taken to their new home: Ground Zero. They originally come from the three places where people died: New York, Pennsylvania and the Washington, D.C. area.

RONALDO VEGA: We have over 400 trees. Swamp white oak is the predominant species. Now we're putting a brand new dress on them to bring them to the site.

NARRATOR: They will become part of an eight-acre forest on the Memorial plaza. Beneath the plaza, a complex irrigation system has been devised to bring water and fertilizer to each and every tree, but what makes this system truly advanced is the sensor technology embedded in the soil.

RONALDO VEGA: These trees have their own, their own computer chip in them. They have their own monitoring system for aeration and irrigation. I mean, each tree has its own little ecosystem, so we know how they, how they're doing. It's all high-tech, real high-tech, and yet, when you look at it, it's just a beautiful little forest.

NARRATOR: Sixteen trees, weighing 18,000 pounds each, are being hoisted and prepared to move. It's a moment that's been a long time coming.

RONALDO VEGA: It's a magical time today. There's nothing like planting a tree.

Perfect, beautiful.

I don't want to say it's solemn, but it's respectful. It'll give the families a sense that we're really going to do this.

NARRATOR: After nearly a decade, the Memorial is finally nearing its completion. The first 16 trees will soon become 50, then 400, as life returns to Ground Zero.

RONALDO VEGA: It's going to bring life. At the same time, it is going have its own cycle of life, death and renewal, which is what trees do.

NARRATOR: And finally, the last major milestone: the installation of the panels etched with the names of the people who lost their lives.

One-hundred-fifty-two panels will surround the pools. For Michael Arad, it's the final step to complete his vision, as the day of the Memorial's opening draws close.

MICHAEL ARAD: What's going to happen after September 11th, is that we're going to open it to the public, and it's going to completely change. And I'm very curious to see how, how it will be received, how it will be experienced, what place it will have in people's hearts and minds, you know?

PAULA BERRY: There's so many things that I suspect will hit people when they come here. We're commemorating the lives of close to 3,000 people and the humanity that was lost, and the humanity that came forward, not just for the family members alone, I mean, this is done for the world. It's an expression of how we respond to an event like this.

CHRIS WARD: Tragically, an opportunity was had, and out of that terrible, terrible destruction, something still wonderful and creative and beautiful could come from it.

NARRATOR: The rebuilding of Ground Zero won't be finished for years. But One World Trade Center is well on its way to completion.

David Childs' original concept to cover the concrete podium with prismatic glass has been scrapped. Its replacement is yet undecided. But many of this skyscraper's safety features are likely to make it one of the most influential buildings in America.

DAVID CHILDS: It is very important that we did rebuild, and it gave us a chance to rebuild better. And that's the, really, the glory, I think, of this, of the statement that we came back.

NARRATOR: The Memorial will open on the 10th anniversary of 9/11, just as those responsible for it promised.

MICHAEL BLOOMBERG: History will look back on how we pulled together as a country and as a city, what we built. The Memorial will be something that we'll look at the way we look at Central Park and say, "How could you not have it? It must have been here forever."

NARRATOR: On September 11, 2011, this site, Ground Zero, will change its meaning, from a long-watched and sometimes criticized construction site, to a place of public gathering for all the people who helped create it, and for people from all over the world.

Broadcast Credits

Engineering Ground Zero

- PRODUCED AND DIRECTED BY

- David Shadrack Smith

- STORY BY

- Timothy Smith

- TELESCRIPT BY

- Timothy Smith & David Smith

- EXECUTIVE PRODUCERS FOR DOCERE STUDIOS, INC.

- Timothy Smith

Anthony Cicatiello - SENIOR PRODUCER

- Terri Randall

- CO-PRODUCERS

- Tennaly Fortier

Jeff Seelbach - EDITED BY

- Jeremy Siefer

- ASSOCIATE PRODUCERS

- Kelly Costigan

Frank Lopez - CINEMATOGRAPHERS

- David Shadrack Smith

Daniel Traub - ADDITIONAL CAMERA

- Marcus Burnett

Mitch Farkas

Peter Hutchens

Mark Petersson

Lauren Terp - SOUND RECORDISTS

- Kristian Borysevicz

Luis Granados

Merce Williams - NARRATED BY

- Lance Lewman

- MUSIC

- Justin Melland

- ANIMATION

- Pixeldust Studios, LLC

- ADDITIONAL EDITOR

- Robert Austin

- ASSISTANT EDITORS

- Andrew Baxt

Andrew Jenter - ONLINE EDITOR

- Will Cox

- AUDIO MIX

- Jacques Boulanger

- RESEARCHERS

- Jeff Friedrich

Suzanne Levingston - PRODUCTION ASSISTANTS Anita Kirpalani

- ARCHIVAL MATERIAL

- 9/11 Memorial & Squared Design Lab

Associated Press

CNN Image Source

Corbis

Getty Images

Great Projects Film Company

Thomas Hoepker/Magnum Photos

ITN Source

John Labriola

Thought Equity Motion/BBC

Silverstein Properties

Skidmore, Owings & Merrill

WGBH - SPECIAL THANKS

- Francis Barry

Marc Becker

Michael Frazier

Alan Hicks

Michael Hurley

Richard Kielar

Amanda Konstam

Elizabeth Kubany

Norma Manigan

Kevin Murphy

Frank Pita

Lynn Rasic

Paul Sanderson

Catherine Yrissari

The National September 11 Memorial & Museum

SOM - Skidmore, Owings & Merrill, LLP

Tishman Construction - NOVA SERIES GRAPHICS

- yU + co.

- NOVA THEME MUSIC

- Walter Werzowa

John Luker

Musikvergnuegen, Inc. - ADDITIONAL NOVA THEME MUSIC

- Ray Loring

Rob Morsberger - POST PRODUCTION ONLINE EDITORS

- Michael H. Amundson

- Spencer Gentry

- CLOSED CAPTIONING

- The Caption Center

- PUBLICITY

- Eileen Campion

Victoria Louie - MARKETING AND PUBLICITY

- Karen Laverty

- SENIOR RESEARCHER

- Kate Becker

- NOVA ADMINISTRATOR

- Kristen Sommerhalter

- PRODUCTION COORDINATOR

- Linda Callahan

- PARALEGAL

- Sarah Erlandson

- TALENT RELATIONS

- Scott Kardel, Esq.

Janice Flood - LEGAL COUNSEL

- Susan Rosen

- ASSOCIATE PRODUCER POST PRODUCTION

- Patrick Carey

- POST PRODUCTION EDITOR

- Rebecca Nieto

- POST PRODUCTION MANAGER

- Nathan Gunner

- COMPLIANCE MANAGER

- Linzy Emery

- DEVELOPMENT PRODUCERS

- Pamela Rosenstein

David Condon - SUPERVISING PRODUCER

- Stephen Sweigart

- BUSINESS AND PRODUCTION MANAGER

- Jonathan Loewald

- SENIOR PRODUCER AND PROJECT DIRECTOR

- Lisa Mirowitz

- COORDINATING PRODUCER

- Laurie Cahalane

- SENIOR SCIENCE EDITOR

- Evan Hadingham

- SENIOR SERIES PRODUCER

- Melanie Wallace

- EXECUTIVE PRODUCER

- Howard Swartz

- MANAGING DIRECTOR

- Alan Ritsko

- SENIOR EXECUTIVE PRODUCER

- Paula S. Apsell

David MacLeod

Rueben Pacheco

Rick Ramirez

Producers gratefully acknowledge the cooperation of the Port Authority of New York and New Jersey

A NOVA production by part2 pictures LLC and Docere Studios, Inc. in association with NHK for WGBH

© 2011 WGBH Educational Foundation All rights reserved

Image

- (worker on beam)

- Courtesy of the Port Authority of New York & New Jersey

Participants

- John Abbey

- Collavino Construction

- Frank Andolino

- Service Metal

- Michael Arad

- Architect & Designer, 9/11 Memorial

- Cas Bognacki

- Engineer, Port Authority of NY & NJ

- David Childs

- Lead Architect, 1 WTC, SOM

- Frank Colletta

- General Foreman, Benson Global

- Joe Daniels

- President & CEO, 9/11 Memorial

- Paul Goldberger

- Architecture Critic, The New Yorker

- Duane Graveno

- ArcelorMittal Coatesville

- Farish Jenkins

- Anatomist, Harvard University harvardscience.harvard.edu/directory/researchers/farish-jenkins-jr

- Lou Mendes

- Supervisor, 9/11 Memorial

- Jim Moretti

- President, Service Metal

- George Pataki

- Governor, New York, 1995-2006

- Chris Ward

- Executive Dir., Port Authority of NY & NJ

- Charlie Woznick

- Collavino Construction

- Jeff Yigdall

- Engineer, PPG Industries

Preview

Full Program

Full program available for streaming through

Watch Online

Full program available

Soon