|

|

|

Part 2 | Back to Part 1 So how does AFI work? First, a laser illuminates the subject with a pattern of stripes, or fringes. The pattern comes from splitting the laser beam into two point sources of near-infrared light, each bearing a wavelength of 780 nanometers (780 billionths of a meter). By making fine adjustments to the two sources of light, operators can manipulate the thickness and placement of the fringes - hence the term Accordion Fringe Interferometry. (Interferometry is the measuring of objects using interference patterns as a tool.) To take accurate readings of complex shapes, such as a nose, operators must be able to adjust the fringes. Initially, they lay only a few thick fringes over the subject, allowing a reading of the general outline of the head. When they thin the fringes to get a more accurate reading, that understanding of the general shape becomes crucial in order to fill in the details - seeing the forest despite the trees, you might say. Imagine stripes of light streaming through a venetian blind. Hold a ball up to the light, and the stripes curve around it. If you were to observe the ball from the sun's point of view, however, the lines would appear straight. Exactly how these lines bend depends on the shape and size of the ball. The same principle applies to AFI: An operator takes a picture of a subject covered in stripes of light (fringes) from a known angle. Knowing exactly where these fringes are projected from—the sun, in the venetian blind example—together with how they appear to bend as viewed from that angle, is enough to triangulate the height of each individual point.

Potential uses go far beyond detective work. Shirley and company fully realize how invaluable knowing the exact dimensions of a car door, satellite dish, or airplane wing, precise to a few hundred nanometers, would be to manufacturers. (Scalability is another of the system's strengths; the same principles that work on a square inch work just as well on an object measuring hundreds of feet square.) Imagine enhanced "virtual reality" games with photo-realistic, 3-D characters and places, or faxes and copying machines that offer printouts in three dimensions. With 3-D printers already on the market, such machines are anything but pie-in-the-sky. Rob Meyer is Production Assistant of NOVA Online. The technology reported here was developed at Lincoln Laboratory and was sponsored by the Department of the Air Force under Air Force Contract #F19628-95-C-0002. Opinions, interpretations, conclusions and recommendations are those of the author and are not necessarily endorsed by the United States Air Force. Images courtesy of Lincoln Laboratory Chronology of a Murder | Science in the Courtroom Create a DNA Fingerprint | 3-D Mug Shot | Cleared by DNA Resources | Transcript | Site Map Editor's Picks | Previous Sites | Join Us/E-mail | TV/Web Schedule About NOVA | Teachers | Site Map | Shop | Jobs | Search | To print PBS Online | NOVA Online | WGBH © | Updated November 2000 |

A diagram showing the splitting of the laser light

into two beams, which results in the fringes that lie

at the heart of AFI.

A diagram showing the splitting of the laser light

into two beams, which results in the fringes that lie

at the heart of AFI.

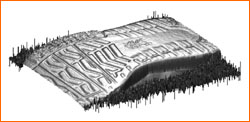

In the near future, detectives may be able to compare

3-D photos of shoe soles (above) with corresponding

3-D images of shoeprints shot at crime scenes.

In the near future, detectives may be able to compare

3-D photos of shoe soles (above) with corresponding

3-D images of shoeprints shot at crime scenes.