|

|

|

Escape through Time

Fire |

Car |

Plane |

Ship

Brakes

The first cars had brakes only on the back wheels, which led

to much skidding and swerving. Like coaster brakes on a

bicycle, rear-only brakes needed long distances to bring the

vehicle to a complete stop. (In 1902, for instance, the

Automobile Club of America found that to stop a car going 20

mph required an average of 60 feet.) Brakes on all four wheels

did not appear in the United States until 1920, when they were

introduced in high-priced cars. It wasn't until the advent of

the new Ford Model A in 1927 that four-wheel brakes became

standard fare in most cars.

|

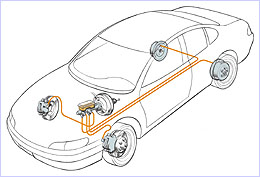

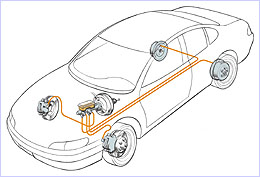

Instead of mechanical rods and cylinders, hydraulic

four-wheel brakes employ the use of fluid pressure to

actuate the brake pads of each of the wheels. Modern

brake systems split the hydraulics into two subsystems

to safeguard the complete loss of brakes.

Instead of mechanical rods and cylinders, hydraulic

four-wheel brakes employ the use of fluid pressure to

actuate the brake pads of each of the wheels. Modern

brake systems split the hydraulics into two subsystems

to safeguard the complete loss of brakes.

|

In the 1930s, hydraulic four-wheel brakes came into use. They

were an improvement over the mechanical variety, except that

when hydraulics were lost, so were all four brakes. Europe led

the way to a new system: dual hydraulic brakes. These systems

consisted of two parts: If a hydraulic leak occurred in one

part, the other could still function, albeit with less

efficiency. Despite their obvious utility, dual hydraulic

brakes weren't fully embraced in the United States until 1961,

when the American Motors Corporation built the system into all

of its cars. The 1950s marked the advent of power brakes,

which increase the amount of hydraulic pressure pushed towards

the master cylinder with the help of a booster. Most modern

brakes today consist of some combination of power and dual

hydraulic brakes.

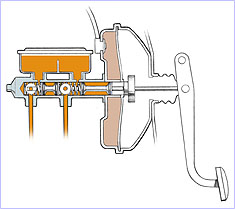

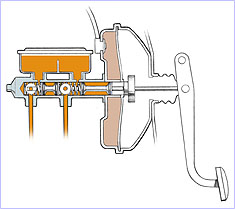

Power brakes involve the use of a master cylinder and

booster to improve the effectiveness of a car's

braking system. By creating an air vacuum within the

booster, a power brake can magnify the force of a

depressed brake pedal and apply greater fluid pressure

to the individual wheels.

Power brakes involve the use of a master cylinder and

booster to improve the effectiveness of a car's

braking system. By creating an air vacuum within the

booster, a power brake can magnify the force of a

depressed brake pedal and apply greater fluid pressure

to the individual wheels.

|

|

Until recently, however, braking on slippery surfaces was

still a risky proposition. Under such conditions, a braking

wheel might "lock up" in its position and begin to slide

without steering control. To combat this, automakers devised

anti-lock brakes. Relying on a computer to monitor the speed

of each wheel, the car can tell when a wheel is beginning to

slide and can apply an automatic series of braking pulses,

which are faster than those created by a human driver.

Anti-lock brakes can stop a car faster in such a situation

than a human driver can and also allow the driver to maintain

steering control.

back to top

Windshield

|

The use of plate glass in early windshields created

the danger of the "glass necklace," a situation in

whic passengers could fly headlong into and through

the windshield during a head-on collision.

The use of plate glass in early windshields created

the danger of the "glass necklace," a situation in

whic passengers could fly headlong into and through

the windshield during a head-on collision.

|

The earliest windshields, introduced by 1904, were folding

affairs. When mud, rain, or other substances blocked his or

her view forward, a driver could simply tip the top half down

for an unobstructed view. (Goggles came in handy in those

situations.) While the usefulness of windshields was clear to

everybody, they posed a serious danger. Manufacturers quickly

discovered that during an accident, their glass windshields

could shatter, sending a shower of sharp shards into the

vehicle. Glass windshields proved most hazardous during

front-end collisions, when passengers could end up smashing

headlong through the glass. Not surprisingly, when the first

cars with glass on all four sides were introduced, many people

were afraid to ride in them.

Early this century, two European scientists independently

invented a solution to deadly windshields. While working in

his lab, French scientist Edouard Benedictus accidentally

knocked a flask to the floor. To his amazement, the glass did

not break. Looking closer, he discovered that the chemical

that had been inside the flask, nitrocellulose, had dried up,

leaving an adhesive film that kept the numerous bits of

fragmented glass from separating. Benedictus went on to

develop a window consisting of two layers of plate glass held

together by layer of cellulose.

Laminated safety glass consisted of two layers of

plate glass held together by a layer of cellulose.

Laminated safety glass consisted of two layers of

plate glass held together by a layer of cellulose.

|

|

Meanwhile, on the other side of the channel, British inventor

John C. Wood had also been working with cellulose and had come

up with his own method for cementing a layer of celluloid

between two pieces of glass. Wood's shatter-resistant glass

came to be produced under the brand-name of Triplex. Though it

was first developed in 1905, Triplex was not brought to the

U.S. until 1926. A year later, Ford began incorporating

laminated glass into each of its automobiles.

In the 1950s, cars came off the line with side and rear

windows of tempered glass. Tempered glass is made by placing

one piece of glass into an atmospheric oven, which heats and

hardens the glass. This treated glass can withstand forces of

hundreds of pounds per square inch. When broken, it breaks

into smooth beads that do not cut the skin, and unlike safety

glass, rescuers can cut into it to reach victims trapped in a

car.

back to top

Seat Belt

|

Early seat belts, sometimes known as lap belts

because they crossed over a passenger's lap, improved

the safety of the automobile passenger.

Early seat belts, sometimes known as lap belts

because they crossed over a passenger's lap, improved

the safety of the automobile passenger.

|

The seat belt was introduced in 1949 by Nash Motors, but it

was not until the mid-1950s that most automakers began

offering seat belts as optional safety features. These safety

belts crossed over a passenger's lap, securing him or her to

the seat in order to prevent a collision with the dashboard,

steering wheel, or windshield in an accident. While the seat

belt vastly improved a passenger's safety, it remained far

from perfect, and nasty head, spinal, and other injuries

continued to occur.

Nils Bohlin, inventor of the three-point belt,

demonstrates its ability to secure a passenger's torso

and center of gravity through a combination of the

principles behind lap and diagonal belts.

Nils Bohlin, inventor of the three-point belt,

demonstrates its ability to secure a passenger's torso

and center of gravity through a combination of the

principles behind lap and diagonal belts.

|

|

Recognizing this, Volvo designed a diagonal two-point belt.

Rather than simply securing your hips, the belt would hold

your upper torso to the chair as well. As they watched tapes

of crash tests, however, Volvo engineers realized the diagonal

belt was flawed. It crossed the body well above the center of

gravity. As the force of a collision rippled through the car,

the test dummy would slip downward and under the safety belt,

which became a kind of clothesline that caught the occupant's

neck and chin, resulting in neck injuries and possible

decapitation. To solve the problem, Volvo engineer Nils Bohlin

created the three-point seat belt. The lap belt held the body

in place while the diagonal shoulder belt kept the torso from

colliding with the structure of the car. First installed in

the 1959 Volvo, three-point seatbelts would not be required in

American cars for another decade.

In 1981, Mercedes-Benz improved the design by adding pre-crash

tensioners. Within milliseconds, seat belt pre-tensioners

tighten safety belts and help prevent belted occupants from

sliding and bouncing around during a crash. Six years later,

Mercedes-Benz, along with Audi, also added shoulder belt

height adjusters to provide a tighter fit.

Today, seat belts are recognized as a passenger's primary line

of defense. According to the U.S. National Highway Safety

Transportation Agency (NHSTA), lap/shoulder belts, when used

properly, reduce the risk of fatal injury to front-seat

passengers by 45 percent, and the the risk of

moderate-to-critical injury by 50 percent.

back to top

Air Bag

In 1952, after witnessing the speed at which a Navy torpedo

canvas could be filled by compressed air, John Hetrick was

granted the first patent for what would become the predecessor

to the airbag. Despite the airbag's obvious utility, it would

take nearly two decades for automakers to become convinced of

their importance.

|

Through a series of crash tests, engineers and safety

experts determined what was needed to make the airbag

a successful safety feature.

Through a series of crash tests, engineers and safety

experts determined what was needed to make the airbag

a successful safety feature.

|

In 1970, the newly founded NHSTA, alarmed by the fact that

fewer than 15 percent of all Americans wore seatbelts, began

to look for new ways to protect accident victims. Hetrick's

airbag concept was seen by many as the ultimate passive

restraint, even though manufacturing safe airbags would

clearly be an enormous challenge. Engineers had to determine

how big the bag should be, what materials should be used in

it, and how to inflate it within 30 milliseconds after impact

without blowing it apart. These challenges were met, however,

and by 1980, Mercedes began offering airbags as standard

equipment. Eight years later, all U.S. car manufacturers were

required to follow suit.

By the late 1990s, a rising number of airbag-induced deaths

had created a new concern: the airbag itself could be

dangerous. The explosive force of a filling airbag was

powerful enough to injure and possibly kill both adults and

children. In almost every case, airbag injuries involved women

under 5'4" or adults and children who were either unbelted or

improperly restrained.

As a solution to the growing number of airbag-induced

injuries, automakers devised a new design, which

incorporated the use of multiple sensors to calculate

the rate and speed of airbag deployment. Depending on

circumstances, airbags would engage one, two, or no

initiators.

As a solution to the growing number of airbag-induced

injuries, automakers devised a new design, which

incorporated the use of multiple sensors to calculate

the rate and speed of airbag deployment. Depending on

circumstances, airbags would engage one, two, or no

initiators.

|

|

In late-model autos, a computer decides how airbags should

deploy. It uses an electronic scale that directs the bag to

deploy only if the rider is above a certain weight, and it can

deploy at two different speeds using one of two initiators. In

a minor accident, only one initiator fires, and the bag

inflates more softly and to a smaller size; in a high speed

accident, both initiators fire.

back to top

Crumple Zones

The same year that Volvo engineer Nils Bohlin invented the

three-point safety belt, Bela Berenyi, an engineer at

Mercedes, came up with a safety concept that would completely

change how cars were designed and built. Prior to 1959, people

believed the stronger the structure, the safer the car. But in

actuality, such construction proved deadly to passengers,

because the force from impact went straight inside the vehicle

and onto the passenger. Berenyi knew that he would have to

find a way to dissipate the force of a crash before it reached

the passenger. In the end, he designed two "crumple

zones"—one in the front of a car and one in the back.

Crumple zones relied on a skeletal frame of special materials

that would crumple in predictable ways, absorbing the energy

of a collision.

|

Crumple Zones, indicated here in red, were designed

to absorb the energy of a collision by bending and

breaking in a predictable manner. In doing so, the

force of the collision would be diverted away from the

passenger's compartment, thereby keeping him or her

from serious injury.

Crumple Zones, indicated here in red, were designed

to absorb the energy of a collision by bending and

breaking in a predictable manner. In doing so, the

force of the collision would be diverted away from the

passenger's compartment, thereby keeping him or her

from serious injury.

|

First introduced in 1959, crumple zones with rigid cabs are

now the standard in every car made throughout the world. In

the event of a severe frontal collision, the frontal frames

that support the engine are designed to slide underneath the

passenger's compartment. In combination with the crumple

zones, the passenger compartment is often built using

high-tensile steel, which creates a rigid passenger cell often

referred to as a "safety cage." This is enhanced by new

side-impact beams, which are found within car doors.

Previously, in extreme side impacts, these beams could bend

and protrude dangerously into the interior. So companies

developed a special side-impact beam that breaks after

absorbing impact energy.

back to top

Photos/Illustrations: (1,2) George Retseck; (3) Aims

Multimedia; (4) Libbey Owens Ford; (5) National Safety

Council; (6,8,9) NOVA/WGBH Educational Foundation; (7,10)

Mercedes Benz.

Escape Through Time

| Skydive |

Human Response

Survivor Stories

|

Pioneers of Survival

|

Survival Strategies

Resources |

Teacher's Guide

|

Transcripts

| Site Map |

Escape! Home

Editor's Picks

|

Previous Sites

|

Join Us/E-mail

|

TV/Web Schedule

About NOVA |

Teachers |

Site Map |

Shop |

Jobs |

Search |

To print

PBS Online |

NOVA Online |

WGBH

©

| Updated November 2000

|

|

|

Instead of mechanical rods and cylinders, hydraulic

four-wheel brakes employ the use of fluid pressure to

actuate the brake pads of each of the wheels. Modern

brake systems split the hydraulics into two subsystems

to safeguard the complete loss of brakes.

Instead of mechanical rods and cylinders, hydraulic

four-wheel brakes employ the use of fluid pressure to

actuate the brake pads of each of the wheels. Modern

brake systems split the hydraulics into two subsystems

to safeguard the complete loss of brakes.

Power brakes involve the use of a master cylinder and

booster to improve the effectiveness of a car's

braking system. By creating an air vacuum within the

booster, a power brake can magnify the force of a

depressed brake pedal and apply greater fluid pressure

to the individual wheels.

Power brakes involve the use of a master cylinder and

booster to improve the effectiveness of a car's

braking system. By creating an air vacuum within the

booster, a power brake can magnify the force of a

depressed brake pedal and apply greater fluid pressure

to the individual wheels.

The use of plate glass in early windshields created

the danger of the "glass necklace," a situation in

whic passengers could fly headlong into and through

the windshield during a head-on collision.

The use of plate glass in early windshields created

the danger of the "glass necklace," a situation in

whic passengers could fly headlong into and through

the windshield during a head-on collision.

Laminated safety glass consisted of two layers of

plate glass held together by a layer of cellulose.

Laminated safety glass consisted of two layers of

plate glass held together by a layer of cellulose.

Early seat belts, sometimes known as lap belts

because they crossed over a passenger's lap, improved

the safety of the automobile passenger.

Early seat belts, sometimes known as lap belts

because they crossed over a passenger's lap, improved

the safety of the automobile passenger.

Nils Bohlin, inventor of the three-point belt,

demonstrates its ability to secure a passenger's torso

and center of gravity through a combination of the

principles behind lap and diagonal belts.

Nils Bohlin, inventor of the three-point belt,

demonstrates its ability to secure a passenger's torso

and center of gravity through a combination of the

principles behind lap and diagonal belts.

Through a series of crash tests, engineers and safety

experts determined what was needed to make the airbag

a successful safety feature.

Through a series of crash tests, engineers and safety

experts determined what was needed to make the airbag

a successful safety feature.

As a solution to the growing number of airbag-induced

injuries, automakers devised a new design, which

incorporated the use of multiple sensors to calculate

the rate and speed of airbag deployment. Depending on

circumstances, airbags would engage one, two, or no

initiators.

As a solution to the growing number of airbag-induced

injuries, automakers devised a new design, which

incorporated the use of multiple sensors to calculate

the rate and speed of airbag deployment. Depending on

circumstances, airbags would engage one, two, or no

initiators.

Crumple Zones, indicated here in red, were designed

to absorb the energy of a collision by bending and

breaking in a predictable manner. In doing so, the

force of the collision would be diverted away from the

passenger's compartment, thereby keeping him or her

from serious injury.

Crumple Zones, indicated here in red, were designed

to absorb the energy of a collision by bending and

breaking in a predictable manner. In doing so, the

force of the collision would be diverted away from the

passenger's compartment, thereby keeping him or her

from serious injury.